Injection molding is a versatile manufacturing process that has transformed how industries approach production. This technique allows manufacturers to create intricate, high-precision parts quickly and affordably, catering to diverse industries.

From consumer goods to high-tech equipment, injection molding’s applications are far-reaching. This article explores ten injection molding applications where this process plays a vital role in delivering efficiency, scalability, and high-quality results.

Automotive Industry

The automotive sector benefits significantly from injection molding. It is used to produce parts like bumpers, dashboards, and internal components such as cup holders and mirror housings.

The method’s precision makes sure that even small, intricate components can be produced at scale, enhancing the functionality and durability of vehicles. As a result, it aids in producing lightweight, cost-effective parts that meet the automotive industry's stringent standards.

Injection molding also enables the use of durable, heat-resistant materials required in automotive applications. This makes sure parts withstand the harsh conditions vehicles encounter daily, including exposure to high temperatures, UV rays, and moisture.

Medical Industry

The medical field relies on injection molding to produce high-quality, sterile parts that adhere to strict health and safety regulations. Products like surgical tools, implantable devices, and diagnostic equipment are manufactured with the utmost precision to guarantee safety and functionality.

The ability to use biocompatible materials is another reason injection molding is vital for medical applications. For example, it’s used to create components for drug delivery systems like inhalers and insulin pens, which require both precision and high-performance standards.

Electronics Industry

In the electronics industry, injection molding is used to create durable, lightweight enclosures for devices like smartphones, laptops, and home appliances. The precision offered by this process makes sure that components like buttons, USB ports, and connectors meet stringent performance standards.

Additionally, injection molding enables the creation of complex internal parts that contribute to the functionality and aesthetics of electronic devices.

For example, the housings for cell phones and other portable devices are often molded using this process. This allows for sleek designs while certifying durability and ease of assembly.

Food and Beverage Industry

Packaging plays a vital role in the food and beverage industry, and injection molding is integral to producing containers that are safe, functional, and compliant with health regulations. From bottle caps to food-safe containers, injection molding brings a cost-effective way to manufacture products at scale.

Plastic injection molding is especially valuable for creating airtight seals that preserve the freshness of food items. Custom-designed packaging solutions can also help enhance product branding and guarantee that food products stand out on store shelves.

Agriculture Industry

In agriculture, injection molding has revolutionized the manufacturing of farming tools and equipment. The ability to create UV-resistant, impact-resistant, and durable parts certifies that agricultural components withstand the harsh environmental conditions of farms.

From tractor parts and irrigation system components to storage bins and feeding troughs, injection molding gives a cost-effective way to produce large volumes of sturdy items that enhance farming efficiency.

The process’s ability to produce components with intricate designs also plays a significant role in improving the functionality of agricultural tools.

Furniture Industry

The furniture industry has embraced injection molding for creating a variety of durable and aesthetically pleasing components. Injection-molded parts are used in everything from chair bases to table supports. They deliver a combination of strength and design flexibility.

The process’s ability to produce ergonomic shapes and intricate patterns has enabled designers to create modern, functional furniture pieces. Injection molding also facilitates mass production and makes it easier to supply large volumes of furniture components that meet customer demands.

Defense Industry

Injection molding is indispensable in the defense sector, where it is used to manufacture parts that need to withstand extreme conditions. This includes components for aircraft, vehicles, and protective gear, all of which must offer high strength and impact resistance.

In addition to parts for military vehicles, injection molding is also employed to create rugged, lightweight components for helmets, body armor, and communication devices. These parts must not only be durable but also precise and cost-effective to manufacture.

Packaging Industry

In the packaging sector, injection molding is used to produce containers, lids, and sealing mechanisms that certify products are safely transported and stored. The ability to design intricate packaging solutions that are both functional and attractive is one of the key benefits of injection molding in this industry.

Plastic packaging made via injection molding is lightweight, cost-efficient, and can be produced in high volumes. For this reason, it’s a preferred choice for packaging manufacturers. The material's versatility also allows for various types of finishes and enhances both the look and durability of the packaging.

Consumer Goods

From everyday necessary things like toothbrushes and kitchen appliances to toys, containers, and even sports equipment, injection molding plays a major role in the production of consumer goods.

The process allows manufacturers to produce highly detailed, consistent parts that meet strict quality, safety, and performance standards. Its flexibility supports the creation of complex designs that would be difficult or expensive to achieve through other manufacturing methods.

Injection molding is also highly efficient for mass production. This makes it possible to create millions of identical parts at a low cost per unit. Additionally, the ability to combine different materials in one component adds more functionality and versatility.

Musical Instruments

The music industry benefits from injection molding by producing parts for instruments that require high precision and durability. Components such as mouthpieces for wind instruments, guitar picks, and drumsticks are commonly made using this method.

Additionally, injection molding is used to produce accessories like instrument cases and stands. The ability to produce such components at scale allows for affordability and makes them more accessible to musicians at all levels.

How RMA Engineering, LLC Can Help

RMA Engineering, LLC specializes in turning your ideas into fully functional, high-quality products. With our expertise in injection molding and rapid prototyping, we help industries from automotive to healthcare create precise, durable components.

Through our online 3D printing services and 3D post-processing services, we make sure that your designs are brought to life with efficiency and accuracy. Let us help you create innovative solutions that meet your unique manufacturing needs.

Contact us today.

Recent Posts

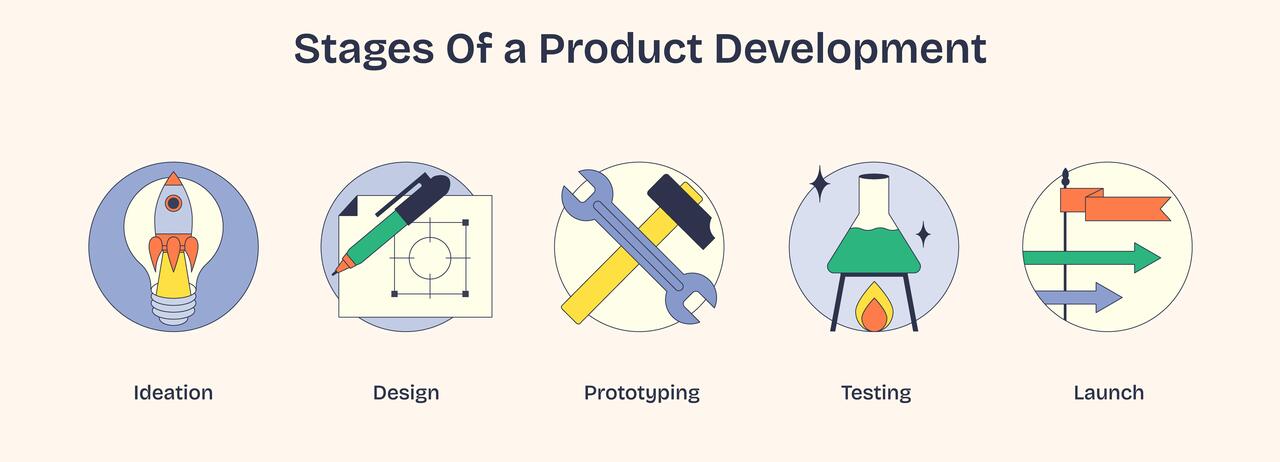

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.