The world of manufacturing demands processes that deliver speed, accuracy, and repeatability. Understanding the advantages of injection molding is vital for businesses aiming to scale production efficiently.

This technique allows companies to create large volumes of parts with high consistency and quality. It supports designs that are complex, yet cost-effective to produce. Injection molding remains a foundation for industries such as automotive, healthcare, and consumer electronics.

For manufacturers that value precision and speed, this process offers solutions that few others can match. It represents a powerful method for turning ideas into reality.

High Efficiency in Mass Production

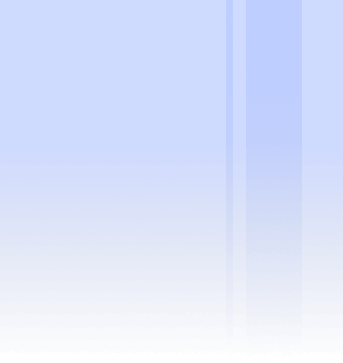

Injection molding is unmatched when it comes to producing large volumes of identical parts at a fast pace.

Once the initial mold is made, the production cycle is quick and reliable. Each cycle can take just a few seconds to complete, depending on the material and design. This fast turnaround helps manufacturers meet tight deadlines and control their inventory better.

For industries where time is a deciding factor, the rapid production of parts becomes a huge advantage. Businesses can respond faster to market demands, reduce lead times, and maintain a steady supply chain.

Ability to Produce Complex Geometries

Injection molding stands out by allowing the creation of intricate and detailed designs that other methods struggle to replicate. Fine features like thin walls, tiny holes, and complex patterns are possible without losing strength or precision.

With carefully engineered molds and high-quality materials, manufacturers can push design boundaries. Industries such as medical technology and aerospace benefit greatly from this capability, where complexity often defines product performance.

This flexibility inspires innovation. Designers are free to imagine parts that are not just functional but also optimized for weight, space, and aesthetics. With injection molding, the limit lies only in the imagination of the design team.

Excellent Repeatability and Consistency

Consistency is a major advantage in high-volume manufacturing. Injection molding guarantees that every part produced mirrors the previous one with incredible accuracy.

The first part made from a mold will look, feel, and perform the same as the millionth. This consistency is evaluative for industries that require tight tolerances and exact measurements, such as medical device manufacturing and automotive parts production. It reduces the risk of defects and improves the reliability of final products.

A consistent process also means less waste, fewer customer complaints, and a stronger brand reputation. For companies relying on brand trust and product reliability, injection molding offers a dependable solution.

Wide Range of Material Options

Manufacturers have access to a broad palette of materials when using injection molding. Options range from strong engineering plastics to flexible elastomers. Each material brings specific advantages, including durability, flexibility, chemical resistance, and heat tolerance.

With the right material, businesses can match product performance to the demands of the environment they will face. Materials can also be colored during the molding process. This will remove the need for post-manufacturing painting or finishing.

This variety allows manufacturers to meet a wide range of project requirements without changing the production method. With access to such choices, design teams gain more freedom to innovate and solve unique challenges.

Low Cost Per Part in Large Volumes

Although creating the mold requires an upfront investment, the cost per unit drops sharply as production numbers rise.

Once set up, the same mold can produce thousands or millions of parts at a very low marginal cost. This economy of scale makes injection molding the method of choice for industries focused on mass production.

Products such as phone cases, automotive components, and kitchenware often use injection molding for this very reason. Saving on unit costs without sacrificing quality can improve profit margins and make products more competitive in price-sensitive markets. Companies that plan for large-volume sales benefit greatly from the cost advantages injection molding delivers.

Reduced Waste During Manufacturing

One of the key advantages of injection molding is its efficiency in material usage. Unlike subtractive manufacturing methods that generate significant scrap, injection molding produces minimal waste.

Excess material—such as trimmings, sprues, and runners—can often be collected, ground down, and reprocessed without compromising product quality. This closed-loop approach supports both cost savings and sustainability.

Injection molding also brings consistent quality and repeatability. This makes it ideal for high-volume production where precision and efficiency matter. For companies seeking ways to lower their environmental footprint while maintaining performance and profitability, injection molding offers a reliable, cost-effective solution.

High Strength and Durability of Parts

Parts made using injection molding can be engineered to deliver high strength and durability. Material choices and design options allow manufacturers to reinforce areas that will face heavy stress. Reinforcing ribs, gussets, and proper wall thickness contribute to longer product life.

Industries such as automotive, aerospace, and healthcare often require parts that can endure extreme conditions, and injection molding delivers this level of performance reliably.

Flexibility In Color and Finish

Injection molding gives the unique ability to integrate color directly into the raw material before the molding process even starts. Adding colorants during the material preparation stage, manufacturers eliminate the need for costly and time-consuming post-production painting or surface treatment.

This built-in approach allows for greater consistency in color distribution. This will result in parts that maintain their appearance throughout the entire product lifespan.

Additionally, injection molding enables a wide range of surface finishes, from glossy to matte and textured effects, through precise mold design.

Minimal Post-Processing Requirements

Many parts created through injection molding come out of the mold nearly finished, requiring minimal sanding, trimming, or other additional finishing work. This efficiency speeds up production timelines and helps manufacturers lower overall labor costs. In many cases, molded parts are ready for immediate assembly or distribution without further refinement.

However, for projects demanding exceptionally high precision or a refined surface quality, specialized services like our 3D post-processing service are available to enhance the final outcome. Reducing the number of production steps, businesses benefit from faster turnaround times, improved part consistency, and more cost-effective manufacturing processes.

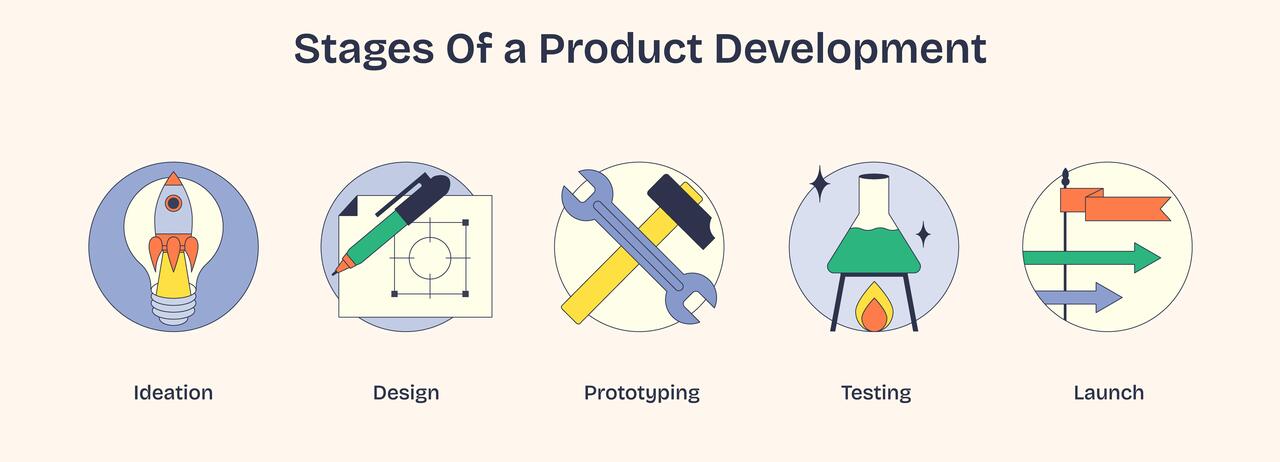

Scalability For Different Production Volumes

Injection molding offers exceptional scalability to accommodate varying production demands. Manufacturers often begin with a limited production run to validate designs, assess functionality, and gauge market interest. Once the product proves successful, the same mold can support full-scale production without needing significant changes.

This flexibility eliminates the need for multiple expensive tooling investments and speeds up the transition from prototype to mass manufacturing. Businesses introducing new products or managing fluctuating market demands benefit greatly from this approach.

Injection molding enables companies to adapt quickly, minimize risks, and allocate resources efficiently. For this reason, it’s a strategic solution for sustainable and scalable growth.

Faster Time-To-Market

Speed brings a powerful advantage in highly competitive industries where timing often determines success. Injection molding accelerates the journey from initial concept to finished product by streamlining the manufacturing process.

Once the mold is developed, production begins quickly without delays linked to traditional methods. Companies can manufacture thousands of identical parts within hours, reduce lead times, and allow faster market entry.

This ability to scale production rapidly helps businesses meet tight launch schedules, respond to sudden demand increases, and stay ahead of rivals. Quick turnaround also improves flexibility and supports product updates and limited-edition releases without major disruptions.

Support For Complex Assembly Needs

Modern injection molding processes enable the combination of multiple components into a single molded part, greatly streamlining manufacturing.

With features such as snap fits, hinges, interlocking joints, and mechanical fasteners directly into the mold design, manufacturers eliminate the need for separate assembly steps. This approach reduces production time, minimizes labor costs, and lowers the risk of assembly errors.

Products become more reliable due to fewer points of mechanical failure. Additionally, integrating multiple features into a single part can lead to lighter designs, stronger connections, and overall better performance. This makes injection molding an efficient choice for complex product development.

Strong Repeatability across Production Cycles

Injection molding guarantees strong repeatability, even after several production cycles. As long as molds are properly maintained, the parts will maintain uniform dimensions and quality.

Consistent output is vital in industries that demand high reliability, such as medical devices and aerospace systems. High repeatability also minimizes defects, which protects brand reputation and reduces waste in long production runs.

A Reliable Partner for Injection Molding Success

At RMA Engineering, LLC, we combine technical expertise with hands-on support to guide your project from concept to completion. Whether you're launching a new product or improving an existing one, our team provides expert consultation in material selection, design for manufacturability, and production scalability. We work with precision and care to deliver results that meet your functional, aesthetic, and timeline goals.

Our injection molding support is backed by a range of related services including rapid prototyping, 3D printing, CAD design, and post-processing. These services allow us to test and refine your designs quickly, helping to minimize risk and reduce lead time. With advanced equipment and a commitment to quality, we create custom solutions that perform.

Let RMA Engineering, LLC be your trusted partner in turning great ideas into manufacturable products—reach out today to get started.

Recent Posts

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.