The Ultimate Guide to Choosing the Right 3D Printing Service

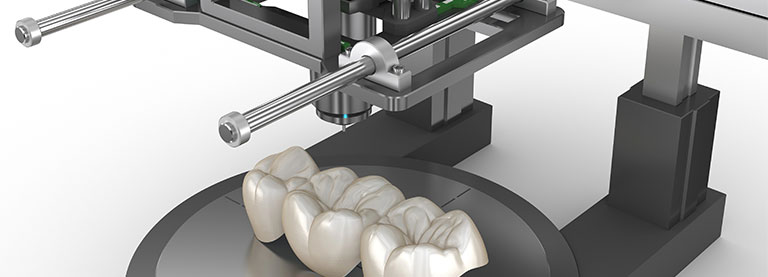

The dental industry has evolved significantly with the adoption of digital technologies. One of the most groundbreaking advancements is 3D printing in dentistry. This technology has redefined traditional workflows by enabling faster production, reducing expenses, and improving precision.

Dentists and dental labs worldwide are leveraging 3D printing to enhance efficiency. This technology allows them to provide patients with high-quality restorations, surgical guides, and orthodontic solutions in a fraction of the time previously required.

How 3D Printing is Changing Dentistry

Traditionally, dental restorations and prosthetics required multiple visits, with molds sent to external labs for fabrication. This process was not only time-consuming but also expensive. It involved multiple professionals and extensive labor.

With 3D printing, dental professionals can produce crowns, bridges, aligners, dentures, and even implants in-house. This shift has transformed the industry–allowing clinics to optimize their resources while improving patient experiences.

The ability to print custom dental solutions directly from digital scans eliminates errors often associated with manual production. In turn, this technology enhances accuracy, minimizes material waste, and streamlines the entire workflow.

Faster Turnaround for Dental Restorations

One of the most significant advantages of 3D printing is its ability to expedite the production of dental restorations.

In the past, patients often had to wait several weeks for a crown or bridge to be crafted and returned from a dental lab. With in-house 3D printing, the same restoration can now be completed in a matter of hours.

This rapid production process is particularly beneficial for emergency cases where immediate dental interventions are required. Instead of relying on temporary solutions, patients can receive permanent restorations almost instantly.

Cost Reduction in Dental Practices

Cost has always been a major factor in dental procedures. Traditional methods involve multiple steps, from creating physical molds to outsourcing work to specialized technicians. Each stage adds expenses related to labor, materials, and shipping.

3D printing eliminates these extra costs by allowing dentists to create dental appliances on-site. The ability to print directly from a digital design removes the need for expensive molds and manual craftsmanship. This significantly reduces overhead expenses.

As a result, practices can offer more affordable treatment options without compromising on quality.

Enhanced Accuracy and Customization

Customization is a key element in dentistry, as every patient requires unique solutions tailored to their specific dental structure. Traditional methods often introduce minor errors due to manual handling. This leads to potential misfits that require further adjustments.

With 3D printing, every restoration or appliance is designed with pinpoint accuracy.

The digital nature of the process makes sure that each component fits perfectly. This reduces the need for remakes or modifications. The precision not only saves time but also improves patient comfort and satisfaction.

Reduced Material Waste

Conventional dental manufacturing processes involve a considerable amount of material waste due to cutting, carving, and molding. These methods often lead to excessive use of materials. This will drive up costs and environmental impact.

3D printing minimizes waste by using only the exact amount of resin or biocompatible material needed for each print. The layer-by-layer fabrication process makes sure maximum efficiency. Therefore, it’s a more sustainable choice for dental practices.

As technology advances, new eco-friendly dental printing materials continue to emerge. This will further reduce environmental concerns.

Streamlined Workflow for Dental Labs

Dental laboratories have traditionally relied on manual craftsmanship and multi-step production techniques. 3D printing simplifies these workflows and allows labs to handle larger workloads while maintaining quality control.

Instead of creating physical models, technicians can now work directly with digital impressions, reducing handling time and increasing production speed. This transition improves operational efficiency and enables labs to meet growing demands without compromising precision.

Improved Patient Experience

Modern patients seek fast, effective, and comfortable dental treatments. The convenience of same-day restorations made possible by 3D printing enhances the patient experience by eliminating the need for multiple appointments.

Additionally, digital scans replace traditional impression molds, which many patients find uncomfortable. The ability to take accurate digital impressions reduces the risk of gag reflexes and enhances the overall treatment process.

Patients benefit from quicker procedures, fewer visits, and high-quality restorations that look and feel natural.

Applications of 3D Printing in Dentistry

3D printing is widely used in various aspects of modern dentistry, transforming the way restorations and appliances are made.

One of the most common applications is in the production of crowns and bridges. With 3D printing, dentists can create custom-fit crowns and bridges within hours. This will significantly reduce wait times for patients. The process enhances accuracy and makes sure of a more comfortable fit compared to traditional methods.

Another important application is the creation of surgical guides. These guides help dentists achieve precision when placing implants, improve surgical outcomes, and minimize the risk of errors. With patient-specific data, 3D-printed guides allow for more predictable and efficient procedures.

Orthodontic aligners also benefit greatly from 3D printing. Instead of relying on conventional braces, clear aligners can be designed and printed quickly. The ability to produce multiple sets in advance allows for a streamlined treatment process tailored to each patient's needs.

Dentures have also seen significant improvements through 3D printing technology. Digital dentures give a superior fit and comfort. They help reduce the number of adjustment appointments needed. The customization options make sure that patients receive prosthetics that closely match their natural teeth.

Lastly, 3D printing supports the production of both temporary and permanent restorations. No matter if a patient needs a quick fix or a long-term solution, this technology enables dental professionals to create high-quality restorations efficiently and affordably.

The Future of 3D Printing in Dentistry

The future of 3D printing in the dental field looks promising, with continuous advancements in materials and printing techniques. Innovations such as bio-printing, which uses cells to print dental tissues, could revolutionize oral healthcare.

Additionally, AI-driven design automation is expected to further streamline production. This will reduce costs and improve efficiency even more.

As adoption rates increase, more dental clinics and labs will integrate 3D printing into their workflows, making advanced dental care more accessible to a broader population. The shift towards digital dentistry is inevitable, and 3D printing is at the forefront of this transformation.

RMA Engineering, LLC recognizes the transformative potential of 3D printing in the dental industry. Reducing production time, lowering costs, and improving accuracy, this technology is transforming the way dental professionals operate. We offer comprehensive design services and post-production solutions so that every step from digital design to final product is seamless.

With continued advancements, 3D printing will further enhance patient care, making high-quality dental solutions more efficient and accessible. Be it for same-day restorations, orthodontics, or surgical planning, 3D printing continues to push the boundaries of modern dentistry.

Recent Posts

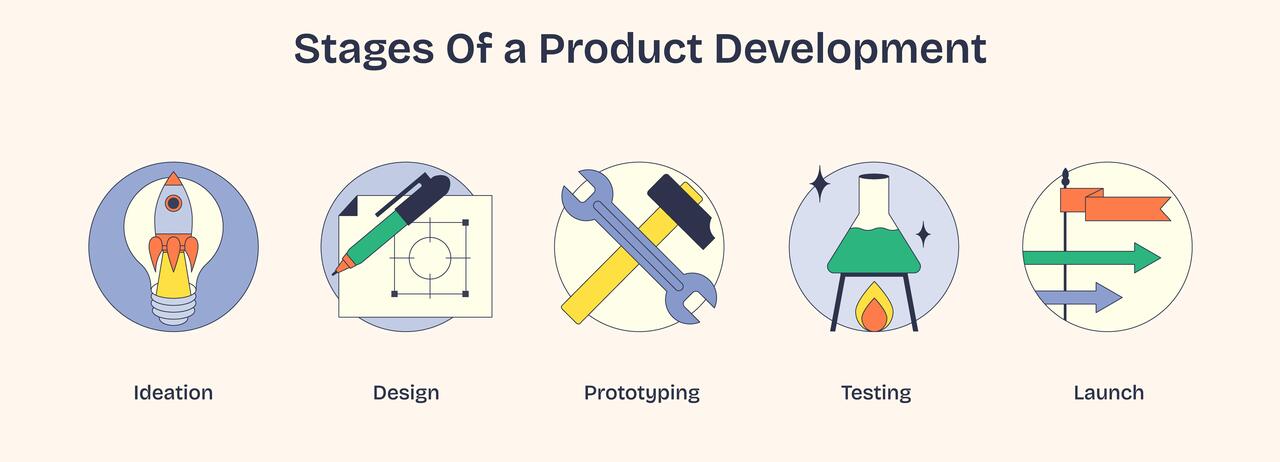

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.