The Ultimate Guide to Choosing the Right 3D Printing Service

Rapid prototyping 3D printing has revolutionized the product development process across various industries. By enabling designers to quickly create prototypes, test designs, and modify concepts, this technology has become a powerful tool in modern manufacturing. The ability to build physical models from digital designs without lengthy manufacturing processes offers several advantages, ranging from cost savings to enhanced flexibility.

Faster Product Development

One of the most compelling reasons companies adopt rapid prototyping 3D printing is the speed it brings to product development. Traditional prototyping can take weeks, as it often involves time-consuming processes like mold creation and manual assembly. Three-dimensional printing drastically reduces this time by allowing for rapid production of functional prototypes, which can be tested and refined more quickly.

By using 3D printing, design teams can compress the product development timeline, resulting in faster market entry. This accelerated development cycle is important for companies aiming to stay ahead in competitive markets. The ability to move quickly from concept to prototype testing without the delays associated with traditional methods improves overall productivity.

Cost-Effective Prototyping

In traditional prototyping, the cost of tools, materials, and equipment can be prohibitively high, especially when working with complex designs or small batch productions. Rapid prototyping with 3D printing eliminates many of these costs by using less material and cutting out the need for expensive molds or specialized machinery. The reduced expense allows companies to experiment with different designs without the financial strain associated with traditional methods.

Additionally, the cost-effectiveness of 3D printing extends to the number of prototypes required. Unlike traditional methods, which may require multiple revisions and costly tooling changes, 3D printing enables rapid iteration at a much lower cost. This flexibility allows for more testing and refining of the product before production, improving the outcome without increasing the overall budget.

Design Flexibility

One of the rapid prototyping with 3D printing features is its ability to support a high degree of design flexibility. Unlike traditional manufacturing methods, 3D printing allows for intricate details that would be difficult to achieve with other techniques. This design freedom empowers creators to experiment with different concepts and functionalities without being restricted by the limitations of conventional manufacturing processes.

Three-dimensional printing makes it easy to modify prototypes as the design evolves. Since no new molds or tools need to be created, changes can be made quickly, reducing both time and cost. This capability is particularly beneficial in industries like automotive or aerospace, where design specifications are continually refined based on testing and feedback.

Reduced Waste and Environmental Impact

Traditional manufacturing methods produces waste, as excess material is removed during the prototyping process. Three-dimensional printing, on the other hand, uses an additive process that builds objects layer by layer, meaning only the material required for the prototype is used. This not only reduces waste but also decreases the overall environmental impact of the prototyping process.

The reduction in waste makes 3D printing a more sustainable alternative to conventional methods, especially in industries that require frequent prototyping or smaller production runs. The environmental benefits are further amplified by the ability to recycle certain materials used in 3D printing, such as plastics and resins. This closed-loop approach minimizes the need for virgin materials, contributing to an eco-friendlier design process.

Improved Communication and Collaboration

In the development of new products, communication between teams is key so that the design meets all functional and aesthetic requirements. Rapid prototyping 3D printing enhances this communication by offering a tangible model that team members can physically interact with. This eliminates ambiguity that might arise from 2D sketches or digital renderings.

Having a physical prototype on hand makes it easier for teams to assess the design from multiple angles and deliver feedback that is based on real-world observations. Additionally, prototypes can be shared with clients, stakeholders, or investors to demonstrate progress and gather valuable input. This hands-on approach to communication helps so that everyone involved in the project is on the same page.

Customization and Personalization

Three-dimensional printing allows for a high degree of customization in prototypes, making it particularly useful for industries that require tailored solutions. From consumer products to medical devices, the ability to adjust the design based on specific customer needs is a significant advantage. With rapid prototyping, companies can create personalized prototypes quickly and affordably, meeting the exact specifications of individual clients.

This customization extends beyond just aesthetics; functional changes can also be made, such as adjusting internal components or incorporating unique features that are specific to a market or user. The flexibility offered by 3D printing sees to it that companies can meet unique demands without needing entirely new production lines or tooling.

Enhanced Testing and Validation

With rapid prototyping, companies can test their designs before committing to mass production, helping to identify issues early in the process. By producing a physical model, engineers can assess factors such as size, functionality, and ergonomics. Testing prototypes under real-world conditions offers invaluable insights that can lead to design adjustments, improving the product’s performance and reliability.

The iterative nature of 3D printing allows for testing multiple versions of a prototype in a relatively short amount of time. This repeated testing and validation help refine the design so that the final product performs optimally in the market. It also offers an opportunity to address any unforeseen issues that may arise during prototype testing, reducing the risk of costly mistakes during full-scale production.

Iterative Design

One of the key advantages of 3D printing is the ability to iterate on designs rapidly. You can produce multiple iterations of a prototype within a short period, enabling you to fine-tune the design based on testing, user feedback, or performance analysis.

This iterative process allows designers to make continuous improvements, reducing the likelihood of costly errors once the product is in full production. By refining the design through multiple iterations, companies can optimize functionality, aesthetics, and user experience more effectively.

The Impact of Rapid Prototyping 3D Printing on Product Development

Rapid prototyping with 3D printing has emerged as a transformative tool in product development. By offering speed, cost savings, and design flexibility, this technology has changed how businesses approach prototyping, making the process more efficient and accessible. It enables faster testing, iteration, and customization, which ultimately leads to better products and more satisfied customers.

At RMA Engineering, LLC, we specialize in rapid prototyping services that help you bring your ideas to life with precision and efficiency. If you are interested in learning more about how rapid prototyping can benefit your next project, contact us today. We are ready to assist with your prototype needs and offer guidance on how 3D printing can streamline your development process.

Recent Posts

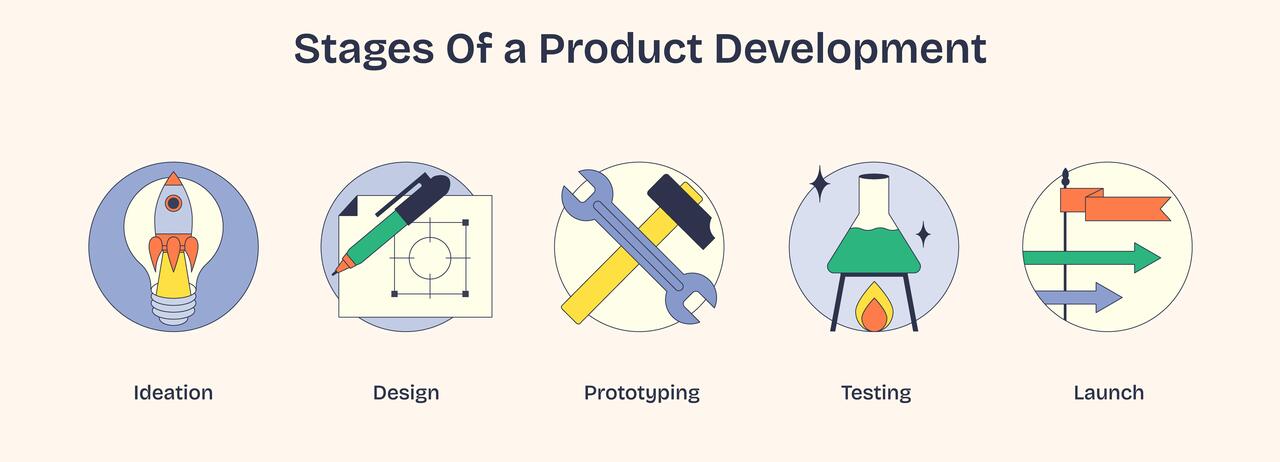

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.