The Ultimate Guide to Choosing the Right 3D Printing Service

Understanding the options in 3D printing is key to making informed decisions for your projects. Among the many technologies available, FDM vs. SLA often stand out as the primary choices for individuals and businesses exploring this dynamic manufacturing method. These two techniques are the most widely adopted in the field, each catering to specific requirements and offering unique benefits. By learning the differences between these technologies, you can confidently choose the method that aligns with your goals.

What is FDM Printing?

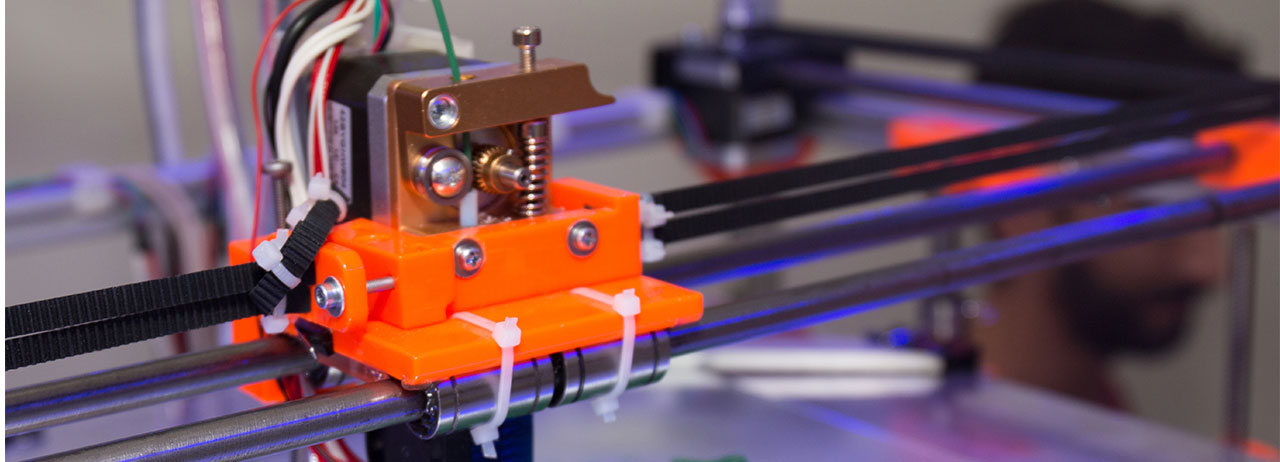

FDM, or fused deposition modeling, is a 3D printing technique that uses a heated nozzle to place the molten thermoplastic filament layer by layer. This process builds the desired object from the bottom up. It is widely recognized for its accessibility and affordability, making it a favorite among hobbyists, educators, and businesses seeking quick and economical solutions for prototypes. Its ability to create functional models and proof-of-concept designs makes it an entry point for those new to 3D printing.

The technology behind FDM is relatively straightforward. It involves extruding material through a nozzle, which moves in pre-programmed paths defined by digital design software. This simplicity allows users to experiment with a wide variety of shapes and sizes. Many industries rely on FDM to quickly iterate designs before committing to higher-quality methods. However, it’s worth noting that while FDM is versatile, its prints often show visible layer lines, requiring additional printing finishing to achieve a smooth surface. This makes it less suitable for applications where appearance or intricate detail is important. Despite these limitations, FDM is an effective tool for creating durable and functional prototypes, especially when speed and cost are top priorities.

What is SLA Printing?

SLA, or stereolithography, uses liquid resin cured by a focused light source, such as a laser or LED, to form objects layer by layer. The process delivers unparalleled precision and smooth finishes, making it ideal for industries requiring intricate designs or high-quality prototypes. SLA is widely used in areas like healthcare, dentistry, jewelry, and product design, where accuracy and material performance are highly valued.

SLA printers rely on photopolymerization, where light activates a chemical reaction to solidify the liquid resin into a solid shape. This results in parts with highly defined details and minimal visible layer lines. The ability to use a wide range of resins allows SLA to accommodate applications requiring flexible, durable, or even biocompatible materials. This makes it an attractive option for professionals who demand not only aesthetic quality but also functional performance. Unlike FDM, SLA parts require additional steps such as rinsing in cleaning solutions and curing under UV light to achieve optimal strength and stability. While these post-processing steps can add time, they significantly enhance the part's overall quality, making SLA the preferred choice for precision work.

Differences in Print Quality

One of the main factors when deciding between FDM and SLA is the quality of the printed objects. FDM is practical for applications where surface finish is not a priority or for producing durable parts quickly. However, the layer lines in FDM prints can affect the aesthetic and structural quality of the final product. These visible lines are often a result of the nozzle's movement and the molten material cooling as it layers.

SLA, by contrast, excels in producing high-resolution parts with smooth surfaces. The precision of SLA printing makes it suitable for creating intricate designs or items that require tight tolerances, such as medical models or functional prototypes for engineering. Additionally, SLA offers unmatched sharpness and detail, making it a popular choice for industries where the smallest imperfections can impact performance. The ability to print parts with nearly seamless finishes ensures that SLA remains a top choice for producing high-quality, visually appealing components.

Ease Of Use and Workflow

FDM printers are known for their user-friendly setup and maintenance. Their straightforward operation makes them a preferred option for beginners or those working with simpler designs. The post-processing for FDM is minimal, often limited to removing support structures or lightly sanding the surface. Users can typically operate an FDM printer with little prior experience, making it a go-to option for schools and small businesses.

SLA printers require more preparation and post-processing. After printing, parts must be rinsed in a cleaning solution to remove excess resin and cured under UV light to strengthen the material. While this adds extra steps, the superior quality and material options often justify the additional effort. Professionals using SLA printers often find the slightly steeper learning curve worthwhile due to the improved precision and material versatility. With automated tools available for rinsing and curing, the workflow has become easier for many users.

Materials and Applications

FDM printers primarily use thermoplastic filaments, such as PLA and ABS. These materials are versatile and available in various colors and blends, making FDM suitable for prototyping, educational purposes, and some end-use parts. They also offer a wide range of specialty filaments, including flexible and reinforced options, allowing for diverse applications across industries.

SLA offers a broader range of materials with specialized properties. Resins can be formulated for flexibility, durability, or even biocompatibility, expanding the scope of applications. SLA is often chosen for industries where material performance and part aesthetics are paramount, including healthcare and high-end product design. The versatility of SLA resins enables it to excel in both prototyping and production, offering users the ability to tackle challenging projects with confidence.

Cost Considerations

Budget often plays a significant role in choosing between FDM and SLA. FDM printers are more affordable upfront, with lower material costs. This makes them a viable option for small businesses or individuals needing functional prototypes without a significant investment. Consumables like filaments are also readily available, making FDM an economical solution.

SLA printers have a higher initial cost and require more expensive materials. However, the quality of the final parts often offsets these costs in professional settings. Businesses looking for detailed and highly accurate components may find SLA a more cost-effective solution in the long run. With advancements in resin formulations and printer technology, SLA continues to grow as a competitive option for those seeking precision without compromise.

Environmental Considerations in FDM and SLA Printing

As sustainability becomes a growing concern, understanding the environmental impact of different 3D printing technologies is important. FDM printers, which rely on thermoplastic filaments like PLA and ABS, often use materials that are recyclable or biodegradable. PLA, in particular, is derived from renewable resources like cornstarch, making it a more eco-friendly option. However, the energy required for heating the nozzle and the filament can contribute to the overall environmental footprint. SLA, on the other hand, uses liquid resins that are not biodegradable and require careful disposal. The post-processing steps, including rinsing and curing, add to the environmental impact due to the use of cleaning solutions and UV light. While SLA prints are of higher quality, users must weigh the ecological trade-offs when choosing this technology for long-term applications.

Durability and Strength in FDM and SLA Parts

The durability and strength of printed parts play a key role in determining the right technology for your project. FDM parts are known for their robustness and can withstand considerable mechanical stress, making them suitable for functional prototypes, jigs, and fixtures. The layered construction does, however, introduce weak points between layers, which can reduce strength in certain orientations. SLA prints, in contrast, exhibit excellent isotropy, meaning they have consistent strength across all dimensions. This feature makes SLA an excellent choice for applications requiring high precision and reliability, such as medical devices and dental implants. The choice between FDM and SLA depends on the balance of structural demands and the required level of detail in the final product.

Scalability for Business Applications

For businesses looking to scale their 3D printing operations, both FDM and SLA offer unique advantages. FDM printers are affordable and can be deployed in large numbers to create a fleet capable of handling high production volumes. Their straightforward operation and lower material costs make them an attractive option for startups and educational institutions with limited budgets. SLA, on the other hand, excels in delivering consistent, high-quality results, which is integral for industries like healthcare and automotive manufacturing. With advancements in SLA printer technology, businesses can now achieve scalability without compromising on detail and precision. By integrating both technologies into a production workflow, businesses can harness the strengths of each to optimize productivity and cost-efficiency.

Choosing the Right Technology for Your Needs

The choice between FDM and SLA depends on your project goals and priorities. If affordability and speed are your main concerns, FDM is an excellent option. It offers a practical solution for functional parts and concept models without demanding high upfront costs. FDM's accessibility ensures it remains a popular choice for those exploring 3D printing for the first time.

On the other hand, SLA is the preferred choice for precision and surface quality. Its ability to produce intricate details makes it ideal for industries requiring high-performance parts or visually appealing prototypes. The wide range of materials available for SLA printing expands its usability, making it a go-to solution for complex applications where aesthetics and performance are equally important.

How RMA Engineering, LLC Can Help

At RMA Engineering, LLC, we guide you through selecting the best 3D printing technology to suit your specific needs. As a trusted partner in the field, we specialize in turning ideas into tangible, high-quality products. With a seamless process and attention to detail, we assist in every stage of the journey, from conceptualization to manufacturing. Our expertise and tailored services make us a dependable choice for both simple prototypes and sophisticated designs.

Both FDM and SLA have their strengths and weaknesses, and the right choice ultimately depends on your objectives. FDM offers a cost-effective and accessible entry point for 3D printing, while SLA delivers precision and surface quality for demanding applications. By understanding the nuances of these technologies, you can confidently select the best method for your unique requirements.

Recent Posts

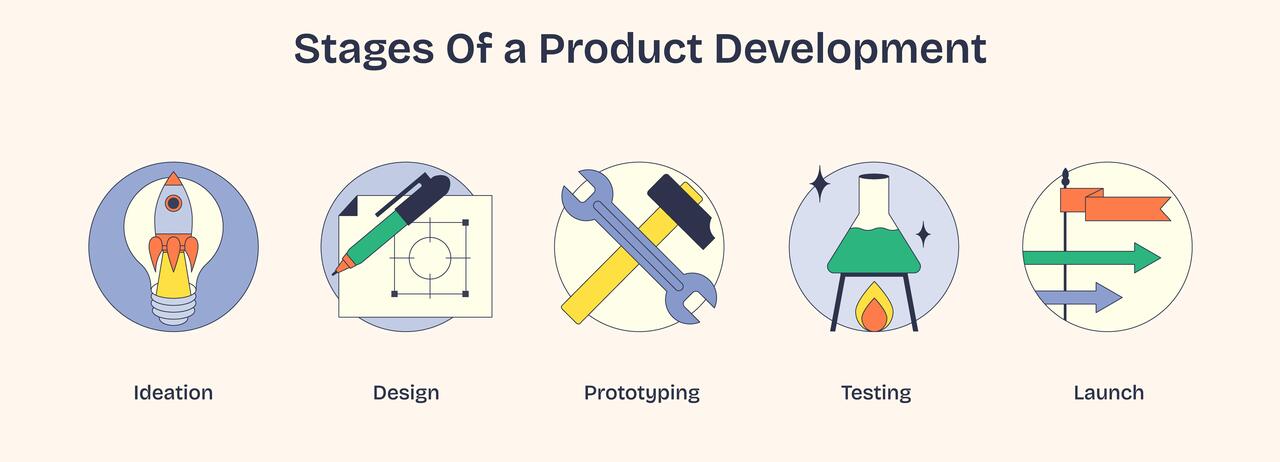

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.