The Ultimate Guide to Choosing the Right 3D Printing Service

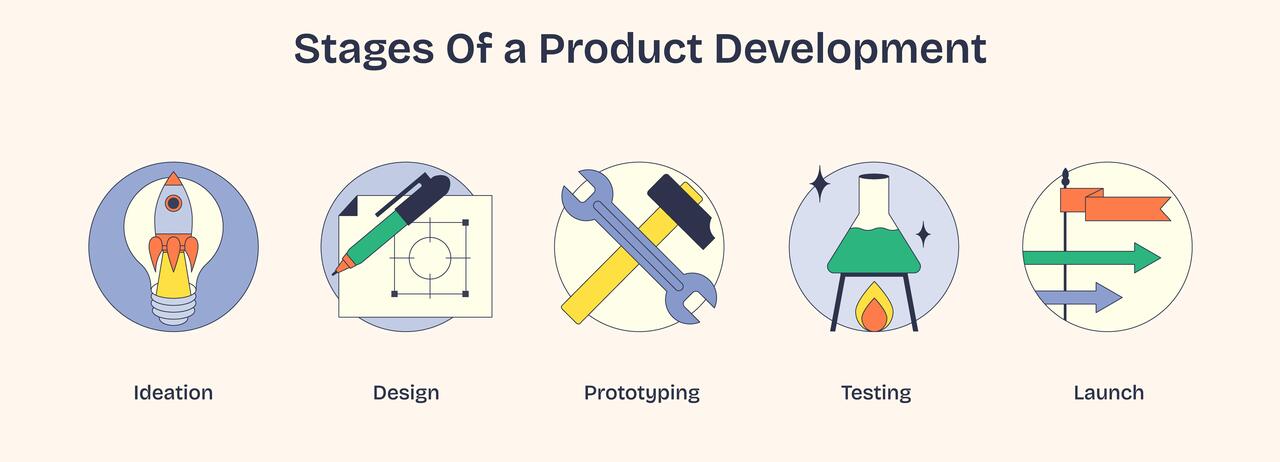

Understanding how to make a prototype is imperative for inventors and creators looking to turn their product ideas into reality. Prototyping is an important step in the development process, helping to test functionality, refine designs, and create a clear path from concept to production. By creating a prototype, you can identify potential improvements, gather valuable feedback, and even attract investors. This guide will walk you through the steps to build a prototype, ensuring your product idea takes shape effectively.

Understanding the Role of a Prototype

A prototype is a preliminary version of your product, created to demonstrate how it looks and works. It can range from a simple visual model to a fully functional item depending on your goals. Prototypes serve as a bridge between imagination and reality, helping you test concepts and gather input before moving to mass production. They allow you to spot design flaws, refine features, and communicate your vision to stakeholders.

For example, a prototype can be a great way to present your idea to potential investors or partners. A physical or digital model makes your idea more tangible, which can be a deciding factor in gaining support. Whether you aim to test market interest, validate your design, or finalize production details, prototyping is a vital part of the journey.

Planning Your Prototype

Before building a prototype, you need to have a clear plan. Begin by identifying the primary purpose of your model. Do you want to test its functionality, showcase its design, or validate its appeal to your target audience? Your goal will determine the type of prototype you need and the materials you should use.

Sketching your idea is a practical starting point. Draw your product and label its key features, imagining how each element will work in real life. Digital tools can help refine your sketches into a more precise design, but a hand-drawn concept is often enough to move forward. The planning stage also involves deciding on the materials and methods that suit your prototype, keeping in mind factors like cost, durability, and ease of use.

Choosing the Right Prototyping Method

There are several ways to create a prototype, each suited to different purposes. If you want to explore your idea quickly and at a low cost, a DIY approach is effective. Materials like cardboard, foam, or clay can be used to build a rough model, giving you a sense of the product’s size, shape, and usability. This approach works well for visual prototypes, which focus on appearance rather than functionality.

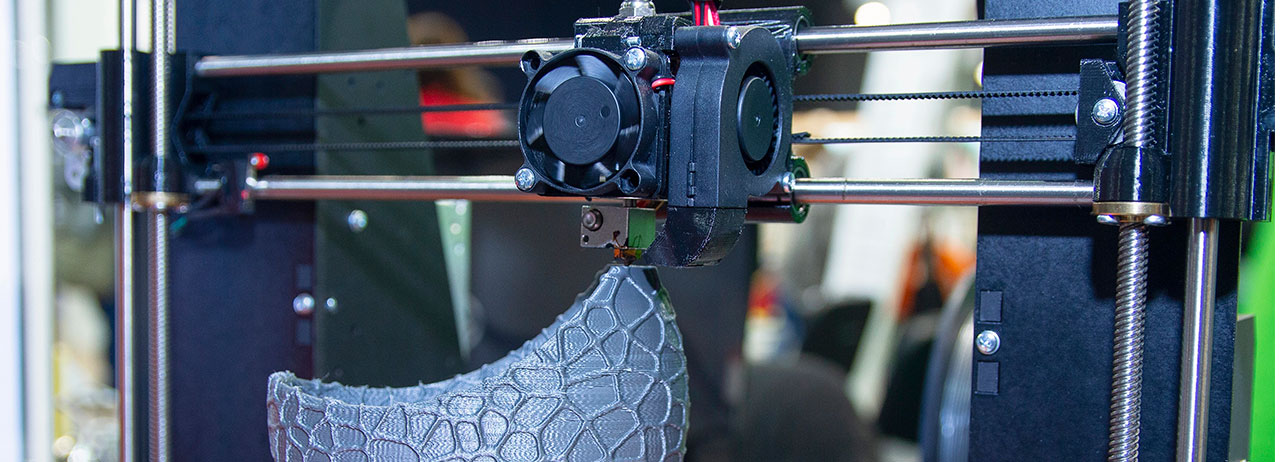

For more advanced prototypes, consider 3D printing. This method allows you to create accurate models with detailed features, making it a popular choice for inventors and businesses alike. 3D printing is fast and cost-effective, especially when testing multiple iterations. Companies like RMA Engineering, LLC, specialize in prototyping services, offering personalized support to turn your ideas into precise models ready for feedback or production. Our expertise in combining design, manufacturing, and innovation ensures a smooth prototyping process tailored to your needs.

Testing and Refining Your Prototype

Once your prototype is complete, testing it thoroughly is essential. Use the model to evaluate its functionality and user experience. Does it work as intended? Are there design aspects that could be improved? Testing should simulate real-world use, revealing potential flaws or areas for enhancement.

Feedback is valuable at this stage. Share your prototype with a sample group, including potential users, industry experts, or trusted colleagues. Their input can uncover insights you may have overlooked, helping you refine your design further. Be prepared to incorporate changes based on feedback, as prototyping is an iterative process. Each revision brings your product closer to perfection, enhancing its chances of success in the market.

Balancing Costs and Efficiency

Prototyping requires careful budgeting, as costs can add up depending on the materials and methods you choose. If you’re working with a limited budget, focus on creating a basic version of your product that still achieves your goals. Simple materials and methods can often deliver the clarity needed to test ideas without excessive spending.

On the other hand, investing in high-quality prototypes can pay off if your project demands precision or if you’re presenting the model to investors. A professionally made prototype demonstrates commitment and boosts confidence in your product’s potential. Balancing cost and efficiency will help you make the most of your resources while staying on track toward production.

Prototyping for Production

Once your prototype meets your standards, it’s time to prepare for production. This step involves finalizing the design, selecting suitable materials, and confirming manufacturing methods. A production-ready prototype should include all the features of the final product, serving as a reference for manufacturers.

Consider creating a small batch of units to test the production process and ensure consistency. This approach allows you to address any issues before committing to large-scale production. By taking the time to perfect your prototype, you set the stage for a smoother manufacturing process and a higher-quality end product.

Collaborating with Experts to Refine Your Prototype

Working with experts can enhance the quality and functionality of your prototype. Professionals such as industrial designers, engineers, or specialized prototyping companies bring technical skills and industry insights to the table. Their expertise can help you overcome design challenges, choose appropriate materials, and optimize production methods. For example, an industrial designer might improve the ergonomics of your product, while an engineer ensures it performs reliably under intended conditions. This collaborative approach not only refines your prototype but also accelerates its journey to production.

By engaging experienced professionals, you gain a fresh perspective on your idea and access to resources that may be beyond your expertise. Companies like RMA Engineering, LLC, excel in offering tailored support for prototyping and manufacturing, ensuring your concept becomes a market-ready product efficiently. Collaboration fosters innovation and paves the way for a successful transition from prototype to finished product.

The Role of Prototyping in Patenting Your Idea

Prototyping plays a key role in protecting your intellectual property, especially when applying for patents. A physical or digital prototype helps illustrate your idea clearly, demonstrating its novelty and functionality to patent examiners. It serves as evidence of your concept's feasibility, making it easier to articulate its uniqueness in patent applications. Moreover, a prototype can help identify any design elements or features that need to be patented, ensuring comprehensive protection for your innovation.

While developing your prototype, you can also spot potential infringements on existing patents, allowing you to make necessary adjustments before filing. Collaborating with an intellectual property attorney during the prototyping phase further strengthens your application, as they can guide you on what aspects to highlight for maximum protection. A well-documented prototype not only supports your patent application but also establishes credibility with investors and partners, reinforcing your ownership of the idea.

Leveraging Prototypes for Market Validation

Prototypes are invaluable tools for gauging market interest and validating your product idea. By showcasing your prototype to potential customers, you can gather real-world feedback on its design, features, and usability. This process helps you identify what appeals most to your target audience and highlights areas for improvement. Conducting surveys, focus groups, or beta testing with your prototype allows you to refine your product based on user insights, ensuring it meets market needs.

Market validation through prototypes also strengthens your pitch to investors, as it demonstrates demand and increases confidence in your idea’s potential success. Additionally, visual and functional prototypes create opportunities for pre-orders, crowdfunding campaigns, or promotional materials that generate early interest and funding. Using your prototype for market validation bridges the gap between concept and commercial viability, giving you the information needed to make strategic decisions about your product’s future.

Integrating Prototyping into the Agile Design Process

Prototyping aligns seamlessly with the agile design process, emphasizing iteration and improvement. In an agile workflow, prototypes serve as a tangible representation of ideas, enabling teams to test and refine concepts quickly. Each iteration builds on user feedback and testing results, leading to a product that evolves to meet market demands. This approach allows for flexibility, as prototypes can be adjusted in response to challenges or changing requirements. Agile prototyping also promotes collaboration among designers, engineers, and stakeholders, ensuring alignment at every stage of development.

By integrating prototypes into an agile framework, you can identify potential issues early and implement solutions efficiently. The iterative nature of this process minimizes the risk of costly redesigns in later stages, ultimately saving time and resources. Prototyping in an agile context fosters innovation and helps create products that truly resonate with users.

Using Feedback to Improve

As you gather feedback on your prototype, look for common themes or repeated suggestions. These patterns often highlight areas that need attention. Addressing concerns raised by users or testers is an opportunity to refine your product and strengthen its market appeal.

Keep your goals in mind when implementing changes. Focus on modifications that enhance usability, solve problems, or improve the product’s overall quality. Avoid making unnecessary adjustments that could complicate the design or increase production costs. The refinement stage is about finding the right balance between functionality, aesthetics, and practicality.

Prototyping is a vital step in bringing your product idea to life. From planning and creating your model to testing and refining it, each stage helps turn concepts into reality. By understanding how to make a prototype, you can confidently move forward in your product development journey, turning ideas into successful outcomes.

Recent Posts

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.