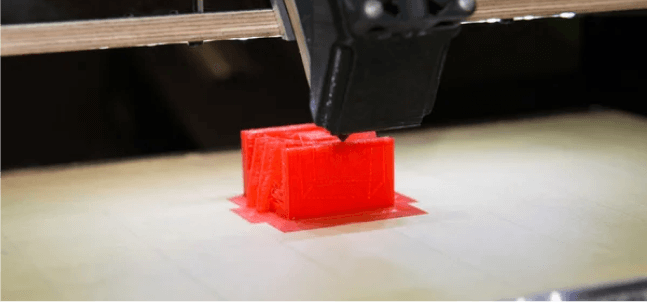

Welcome to our comprehensive guide on 3D printing materials! In the ever-evolving world of 3D printing, choosing the right material for your projects is crucial. Understanding the characteristics, strengths, and applications of different materials will help you achieve optimal results. In this blog post, we'll explore five popular 3D printing materials: PLA, PETG, TPU, polypropylene, and ABS-like resin. By delving into their unique features and highlighting their advantages, we aim to provide you with valuable insights that will help you make informed decisions for your 3D printing projects.

PLA (Polylactic Acid):

PLA is one of the most widely used materials in 3D printing due to its accessibility and user-friendly nature. Here are some key features and benefits of PLA:

PETG (Polyethylene Terephthalate Glycol):

PETG combines the best characteristics of PLA and ABS, making it a popular choice for various applications. Here's why PETG stands out:

TPU (Thermoplastic Polyurethane):

TPU is a flexible filament that offers excellent elasticity and durability. Here's why TPU is a valuable 3D printing material:

Polypropylene:

Polypropylene (PP) is a versatile thermoplastic polymer with numerous industrial applications. While not as common in 3D printing as other materials, it offers specific advantages:

ABS-like Resin:

ABS-like resin is a popular alternative for traditional ABS filament. It offers similar properties while overcoming some of ABS's limitations:

Recent Posts

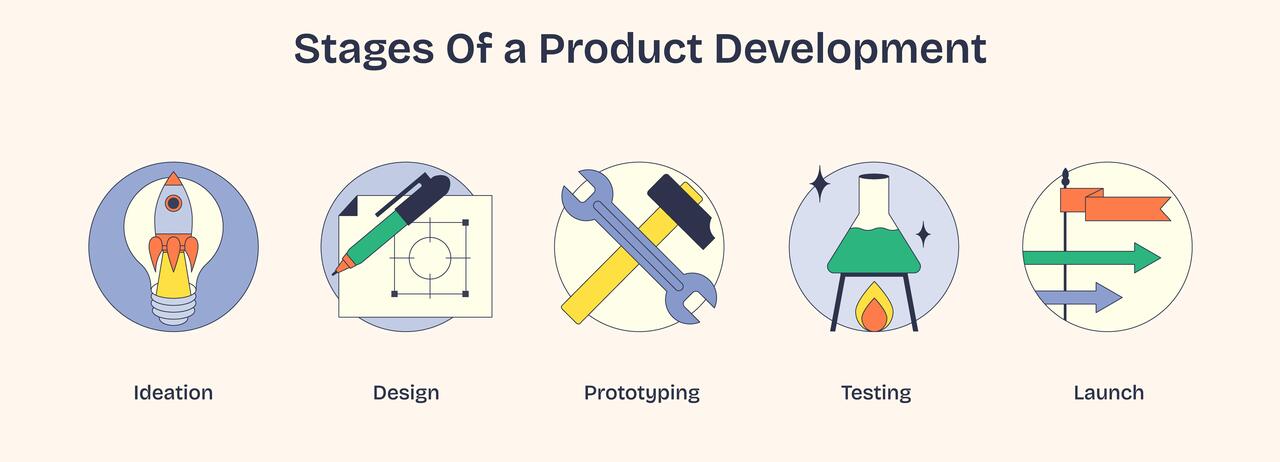

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.