The Ultimate Guide to Choosing the Right 3D Printing Service

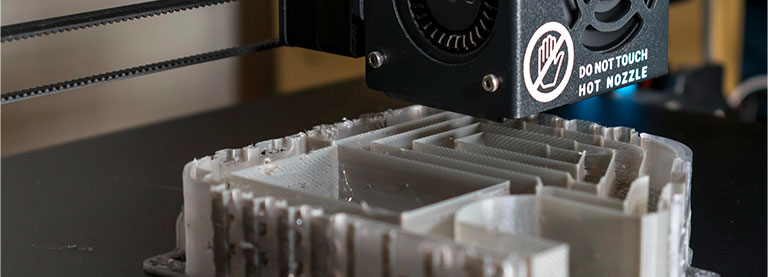

Additive manufacturing, also known as 3D printing, has come a long way since its early days of prototyping. Today, the technology is not only used for creating models but also for producing end-use parts and products in a variety of industries.

With the ability to build complex geometries, reduce material waste, and offer high customization, additive manufacturing is gaining traction. Examples are becoming increasingly common in fields like aerospace, healthcare, automotive, and more.

In this post, we’ll explore some of the most innovative applications of this technology.

Aerospace: Reducing Weight and Enhancing Performance

One of the earliest adopters of additive manufacturing was the aerospace industry, where weight and performance are paramount. 3D printing allows for the production of parts with complex geometries that traditional methods cannot achieve. Consolidating multiple components into one, AM reduces the overall weight of parts. This is important for fuel efficiency in aircraft.

For instance, CFM International’s LEAP turbofan engines, used by Boeing and Airbus, rely on 3D printed components to improve fuel efficiency and reduce environmental impact.

Medical Industry: Customized Implants and Devices

The medical field is another sector benefiting greatly from additive manufacturing. One of the key advantages of AM in healthcare is the ability to create customized implants that are tailored to a patient's specific needs. This is especially important in areas like orthopedics, craniofacial surgery, and dental care.

For example, Straumann uses 3D printing to create custom dental implants from titanium alloys, speeding up production and improving patient outcomes. Similarly, in orthopedics, surgeons can use 3D printing to create patient-specific implants.

One example is the titanium rib cage created for a cancer patient, designed to replace the ribs removed during surgery. AM also enables the creation of anatomical models for pre-surgical planning. This helps improve the accuracy of procedures and reduce recovery times.

Automotive: Lightweight Components for Better Performance

The automotive industry is another key area where additive manufacturing examples are making a significant impact. In particular, AM helps create lightweight components that can improve vehicle performance while reducing fuel consumption.

For instance, Strati, the world’s first 3D printed car, was unveiled in 2014. Made from lightweight plastic, it was designed using additive manufacturing techniques to achieve high strength while keeping weight to a minimum. Beyond concept cars, automotive manufacturers are now using AM for producing functional parts like grilles, custom interior features, and prototypes for new vehicle designs.

With the ability to create parts that are highly customizable and lightweight, additive manufacturing is aiding in the development of electric vehicles (EVs). In this field, efficiency is key to improving battery life and range.

Food Industry: Printing Custom Meals

While it might sound futuristic, 3D printing food is a reality. The food industry has started exploring additive manufacturing for creating custom meals that meet specific nutritional needs.

Companies like Redefine Meat are leading the way with their 3D printers that produce plant-based meat alternatives. These products mimic the taste and texture of real meat without the environmental impact.

This technology could revolutionize food production, especially in remote locations where traditional farming methods are difficult. The ability to print custom meals tailored to a person’s dietary needs could also open up new opportunities in healthcare, particularly for patients with specific nutrition requirements.

Energy: On-Demand, Customized Components

The energy sector is also finding value in additive manufacturing for creating highly durable, custom parts that can withstand extreme conditions. I In industries like oil, gas, and power generation, where equipment must endure harsh environments, AM presents valuable solutions. It allows for the production of corrosion-resistant components that can be tailored to meet specific operational needs.

Additive manufacturing is being used to produce key components like pressure gauge parts, flow meters, and control-valve components. These parts can be produced on demand, reducing lead times. This allows companies to quickly respond to operational challenges without waiting for traditional manufacturing processes to catch up.

As we’ve seen, additive manufacturing examples are revolutionizing industries across the board. From aerospace and healthcare to automotive and consumer products, the potential of 3D printing is immense. It can improve product designs, reduce costs, and offer customization.

As technology continues to evolve, it will likely play an even more prominent role in shaping the future of manufacturing.

RMA Engineering: Helping You Leverage Additive Manufacturing

If you're looking to explore the benefits of additive manufacturing for your business, RMA Engineering delivers a range of services to help you bring your ideas to life. No matter if you need rapid prototyping, low-volume production, or post-processing services, we’ve got you covered.

We specialize in online 3D printing services that provide fast, accurate, and cost-effective solutions for businesses of all sizes. Once your 3D printed parts are ready, our 3D post-processing service makes sure that they meet your specifications, with services like support removal, surface finishing, and painting to give your parts the final touch they need.

If you’re ready to explore how additive manufacturing can benefit your business, RMA Engineering is here to help. Get in touch with us today to learn more about our 3D printing services and how we can support your next project.

Recent Posts

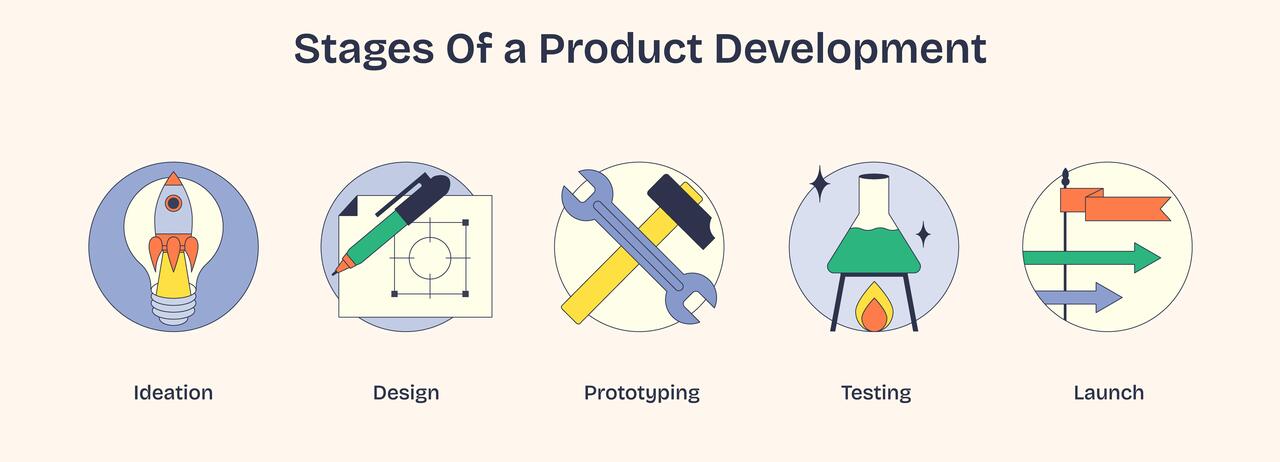

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.