The Ultimate Guide to Choosing the Right 3D Printing Service

The construction industry has long been known for its slow adoption of new technologies, but 3D printing is beginning to change that. With the ability to create complex structures with precision and efficiency, 3D printing construction is transforming the way buildings and infrastructure are designed and built. As a result, it is offering new possibilities for both residential and commercial projects, from faster construction times to cost-effective solutions.

Cost Reduction and Efficiency

One of the most significant benefits of 3D printing for construction is the potential for cost reduction. Traditional construction methods often involve a lot of waste, both in terms of materials and labor. Three-dimensional printing reduces material waste by using only the amount necessary to build the structure, significantly lowering the overall cost. In addition, the labor required for 3D printing is typically much less compared to conventional methods, as the printer can work autonomously for extended periods of time.

Another cost-saving factor is the speed at which 3D printing can complete a construction project. Because the printer can work continuously, projects can be completed in a fraction of the time required for traditional construction. For example, it is possible to print the walls and structural elements of a house in a matter of days, something that would typically take weeks or even months to accomplish with traditional construction. This reduced timeline cuts costs and also makes the process more efficient for builders and contractors.

The reduction in construction time is especially important for large-scale infrastructure projects. Three-dimensional printing allows for the rapid production of complex components, such as bridges or architectural elements, which would otherwise take much longer to create. This results in a quicker completion of the overall project, allowing contractors to move on to new jobs sooner and improving the overall flow of work across the industry.

Customization and Complex Designs

Another exciting aspect of 3D printing in construction is the ability to create highly customized and intricate designs. Traditional construction methods can struggle with complex shapes and unique features, often requiring expensive molds or labor-intensive techniques. With 3D printing, it is easy to produce customized elements that fit specific needs or design aesthetics without significantly increasing costs. Architects and designers can now bring their visions to life with far more freedom and creativity than ever before.

The ability to produce complex designs is particularly valuable for sustainable and energy-efficient buildings. Three-dimensional printing construction can allow for intricate geometric patterns that improve the thermal performance of buildings, helping to reduce energy consumption. This makes it an attractive option for eco-friendly projects that seek to lower their environmental impact while still achieving cutting-edge, modern designs.

In addition to aesthetic customization, 3D printing can also be used to adapt structures to meet specific site conditions. For example, a building can be printed with unique foundations or materials that respond to the local climate or geographical challenges. This flexibility is a game-changer for construction projects in remote or challenging environments, where traditional methods may be more difficult or expensive to implement.

Sustainability and Waste Reduction

Sustainability is an increasingly important concern for the construction industry, and 3D printing is making a major contribution to reducing its environmental footprint. One of the biggest ways it does this is by minimizing material waste. Traditional construction methods often involve significant amounts of excess material that go unused or discarded. In contrast, 3D printing construction produces only the exact amount of material needed to complete a structure, greatly reducing the amount of waste generated during the building process.

Additionally, 3D printing can be used to recycle waste materials into construction components. For example, certain types of 3D printers are capable of using recycled plastic or concrete to create new building materials. This not only reduces the amount of waste that ends up in landfills; it also helps create a more sustainable, circular construction model. By incorporating recycled materials into the printing process, builders can significantly lower their carbon footprint.

The sustainability of 3D printing is also reflected in the energy efficiency of the buildings themselves. The use of advanced insulation techniques and the ability to print in complex shapes can lead to better energy performance, resulting in buildings that are more thermally efficient and cost-effective to heat and cool. As the world moves toward greener construction practices, it is playing an increasingly important role in achieving sustainable building goals.

Speed and Innovation in Construction

Speed is one of the most significant advantages of 3D printing construction. In traditional construction, delays are common due to various factors such as weather, labor shortages, or delays in material shipments. However, 3D printing allows for continuous construction activities that can operate around the clock. The printing process can start immediately after a design is finalized, and with minimal human intervention, it can continue uninterrupted, leading to faster project completion.

The speed of 3D printing also extends to the delivery of materials. Unlike conventional construction, which requires sourcing and transporting materials from multiple suppliers, 3D printing can use locally sourced materials, reducing supply chain delays. This has the potential to revolutionize construction in remote areas, where transportation of building materials can be a significant challenge. Three-dimensional printing could also reduce the reliance on heavy machinery, making construction safer and more efficient.

Moreover, the ability to rapidly prototype and test different designs allows builders to innovate more freely. In traditional construction, making changes to a project mid-construction can be costly and time-consuming. With 3D printing, modifications to designs can be made on the fly, allowing for quicker iterations and experimentation. This makes 3D printing a powerful tool for architects and engineers who are looking to push the boundaries of design and construction.

Post-Processing and Quality Control

After 3D printing construction elements are produced, post-processing is often necessary to refine the final product. This involves smoothing surfaces, adding finishing touches, or making sure that the printed components meet certain strength and durability standards. While 3D printing can achieve a high level of precision, additional work is typically required to meet the specific performance requirements of a project.

A 3D post processing service can help to optimize the final product by improving its structural integrity or appearance. This can include techniques such as polishing, painting, or reinforcing the printed elements. By refining the printed components, construction teams can see to it that the building is both visually appealing and structurally sound and ready for use.

Quality control during the post-processing phase is just as important as during the printing process itself. The printed structure must undergo thorough testing to verify that it meets building codes and regulations. When it comes to checking for strength or assessing thermal insulation properties, post-processing makes it a point that 3D-printed construction meets the same high standards as traditionally built structures.

The Future of 3D Printing in Construction

The future of 3D printing in construction looks bright as the technology continues to evolve. With ongoing advancements in 3D printer capabilities and materials, the construction industry will see even more innovative applications of this technology. From large-scale infrastructure projects to small residential homes, 3D printing has the potential to revolutionize how we think about building.

As the cost of 3D printing technology continues to decrease, it is expected that more and more construction companies will adopt it for their projects. This widespread adoption will further drive innovation, leading to faster and more cost-effective construction methods. Furthermore, as the world faces growing concerns about climate change and resource shortages, 3D printing offers a more sustainable alternative to traditional building methods, making it a key tool in achieving global sustainability goals.

The ongoing development of 3D printing materials and techniques will also allow for greater customization, making it possible to create unique and highly specialized buildings. As these technologies become more refined, the possibilities for 3D-printed structures will only expand, creating a future where almost anything can be built with a 3D printer.

Shaping the Future of Construction with 3D Printing

As 3D printing technology evolves, its influence on the construction industry will only grow. With the ability to create more sustainable, cost-effective, and innovative buildings, the potential for 3D printing in construction is limitless. The technology is transforming how architects, builders, and engineers approach construction, making it possible to bring bold designs to life while reducing waste and time.

In the near future, 3D printing will likely become an integral part of the construction process, expanding beyond residential projects to larger-scale infrastructure. This shift will open doors to smarter, more efficient cities and structures designed with both environmental sustainability and cost-efficiency in mind. The potential to revolutionize construction practices globally is vast, making 3D printing a key player in shaping the built environment of tomorrow.

Transforming the Construction Landscape

Three-dimensional printing in construction is not just a passing trend; it is fundamentally changing the way buildings and infrastructure are created. As the technology advances, the cost and environmental benefits, as well as the speed and precision of construction, will continue to drive its adoption across the industry. For anyone looking to incorporate cutting-edge construction techniques into their projects, 3D printing is a game-changer.

If you are interested in taking advantage of the benefits of 3D printing for your next construction project, look no further than RMA Engineering, LLC. Our online 3D printing services offer innovative solutions for construction and manufacturing. Contact us today to learn more about how we can help bring your vision to life with the latest in 3D printing technology.

Recent Posts

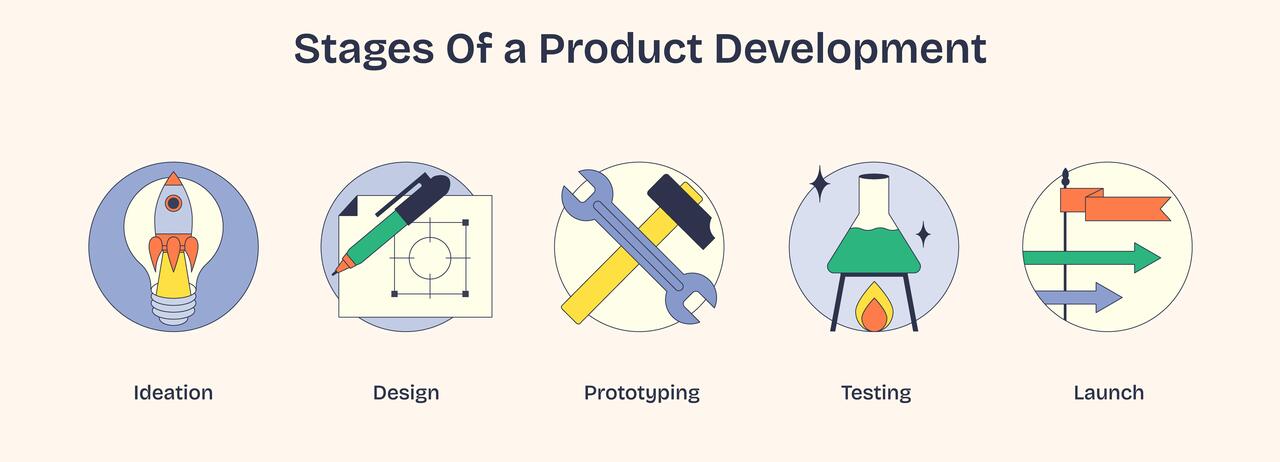

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.