RMA Engineering, LLC understands the unique challenges and opportunities in the field of architecture. Our integrated manufacturing, prototyping, and 3D printing solutions are designed to meet the specific needs of architects. A 3D-printed architectural model, combined with our advanced manufacturing techniques, can provide a range of benefits that enhance the design process, improve communication, and streamline project workflows.

With our expertise and state-of-the-art technology, we empower architects to bring their visions to life with precision, speed, and cost-effectiveness.

Understanding the Architecture Industry

Traditional architectural model-making is a time-consuming and labor-intensive process, often involving materials like foam, cardboard, and wood. This method requires specialized skills and can be prone to human error, leading to inaccuracies and delays.

At RMA Engineering, we leverage a combination of 3D printing and advanced manufacturing technology to transform this process. Our 3D-printed architectural models drastically reduce the time required to create detailed and accurate physical representations of your designs.

This enables architects to focus on other critical aspects of their projects, ensuring timely project completion and increased productivity.

Contact USBenefits of Creating 3d-Printed Architectural Models

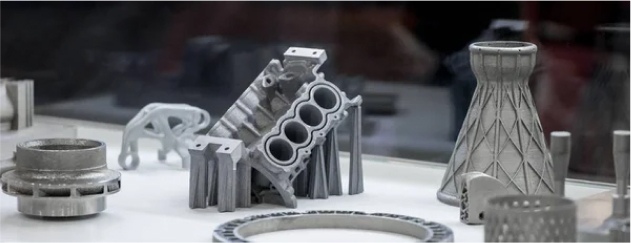

A significant advantage of our integrated approach of manufacturing, prototyping, and 3D printing is its ability to produce highly precise and accurate models. Our advanced 3D printers, coupled with manufacturing techiques, can replicate complex geometries and intricate details that would be challenging to achieve with traditional methods.

- This ensures that the final model is a faithful representation of the intended design, allowing architects to present their concepts with confidence.

- The high level of detail and accuracy also facilitates better decision-making and design validation, reducing the risk of costly revisions during the construction phase.

How We Can Help

- Architectural design is an iterative process that often involves multiple revisions and adjustments. With traditional model-making, making changes to a design can be cumbersome and time-consuming.

- In contrast, our combined manufacturing and 3D printing solutions allow for easy modifications directly to the digital model. Once the changes are made, the updated model can be printed quickly, showcasing the new design without significant delays.

- One of the challenges architects face is effectively communicating their designs to clients who may not have a technical background. Traditional 2D drawings often fail to convey the full scope and spatial relationships of a design.

- Our 3D-printed and manufactured architectural models provide a tangible and realistic representation of the project, making it easier for clients to understand and visualize the final outcome. This improves client satisfaction and ensures that their expectations are met.

- Architectural projects involve collaboration among various stakeholders, including designers, engineers, and contractors. Our 3D models serve as a common platform for all parties to work together seamlessly.

- For example, plumbing engineers can integrate detailed plumbing plans into the model, while electrical engineers can integrate detailed plumbing plans into the model, while electrical engineers can plan the wiring layout. This level of coordination reduces the risk of errors and ensures that all aspects of the project are aligned.

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.