Selective Laser Sintering (SLS)

Selective laser sintering (SLS) is an industrial 3D printing process that produces accurate prototypes and functional production parts in as fast as 1 day. Multiple nylon-based materials and a thermoplastic polyurethane (TPU) are available, which create highly durable final parts that require heat resistance, chemical resistance, flexibility, or dimensional stability. With SLS 3D printing, no support structures are required making it easy to nest multiple parts into a single build and an economical solution for when higher volumes of 3D-printed parts are required.

Common uses for selective laser sintering are:

- Jigs And Fixtures

- Housings

- Snap Fits And Living Hinges

Design Guidelines for Selective Laser Sintering (SLS)

Our basic guidelines for selective laser sintering include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Available Materials

PA 11 Black (PA 850) provides ductility and flexibility without sacrificing tensile strength and temperature resistance. These characteristics make PA 850 a widely used general-purpose material for functional and moving parts.

PA 12 White (PA 650) is a go-to material for general-purpose applications like functional and end-use parts. PA 650 is the strongest of the unfilled nylon materials and it is slightly stiffer than PA 11 Black.

PA12 Mineral-Filled (PA620-MF) is a 25% mineral fiber-filled PA powder. The fiber content significantly increases stiffness and HDT (up to 363 °F). It is a good material option when stiffness and high temperature resistance are important requirements.

PA12 40% Glass-Filled (PA614-GS) is a PA powder loaded with glass spheres that make it stiff and dimensionally stable. This material is an ideal candidate for parts that require long term wear resistance properties. Due to the glass additive, it has decreased impact and tensile strengths compared to other nylons.

Polypropylene Natural offers chemical resistance properties that are top among the SLS and MJF material offerings. This tough and durable, yet flexible, material offers resistance to most acids and is a low weight material option.

TPU 70-A is a white thermoplastic polyurethane that combines rubber-like elasticity and elongation with good abrasion and impact resistance properties. The rubber-like quality of this material make it ideal for seals, gaskets, grips, hoses, or any other application where excellent resistance under dynamic loading is required.

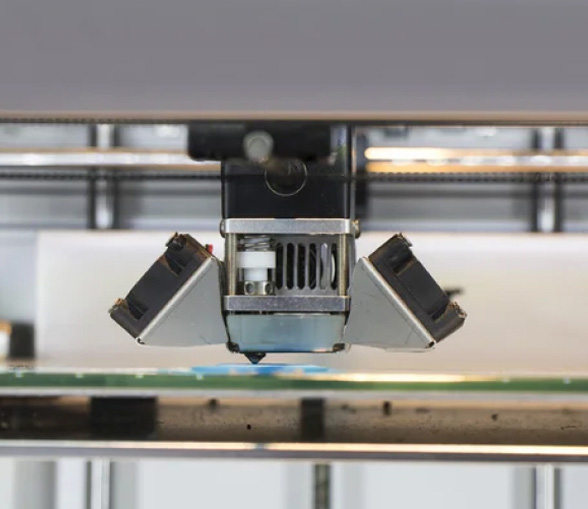

How Does SLS 3D Printing Work?

The SLS machine begins sintering each layer of part geometry into a heated bed of nylon-based powder. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. The process is repeated layer by layer until the build is complete.

When the build finishes, the entire powder bed with the encapsulated parts is moved into a breakout station, where it is raised up, and parts are broken out of the bed. An initial brushing is manually administered to remove a majority of loose powder. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department.

Contact USContact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.