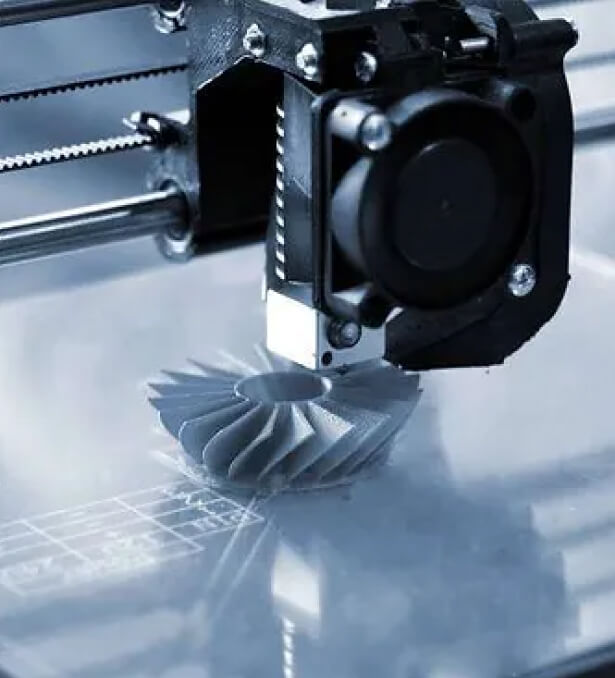

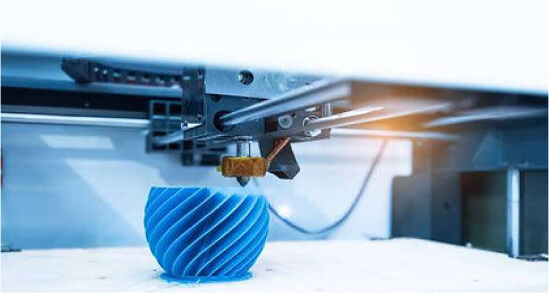

3d Post-Processing Service

We understand that the journey from a digital design to a physical object involves more than just printing. That's why we offer comprehensive 3D post-processing services to ensure that your 3D printed creations achieve the highest standards of quality and finish. With our expertise and

state-of-the-art equipment, we can transform your raw prints into refined masterpieces, ready for any application.

Our Range of Services

Surface Smoothing and Finishing

We take pride in our meticulous approach to surface smoothing and finishing. Utilising a combination of advanced techniques such as sanding, polishing, and precision chemical treatments, we go the extra mile to refine the surfaces of your 3D-printed parts. Our goal is simple: to eliminate layer lines and imperfections, resulting in a flawlessly smooth finish that enhances both the look and feel of your components. Whether it's achieving a mirror-like polish or a satin-smooth texture, our team is committed to delivering unparalleled quality that exceeds your expectations.

Painting and Colouring

Elevate the aesthetics of your 3D printed parts with our expert painting and colouring services. Our skilled artisans are adept at applying a wide range of finishes, from vibrant hues to subtle tones, to bring your vision to life in stunning detail. Whether you desire rich, eye-catching colours, lifelike textures, or bespoke finishes tailored to your specifications, we have the expertise and creativity to make it happen. With our meticulous attention to detail and commitment to quality, you can trust us to transform your prints into works of art that captivate and inspire.

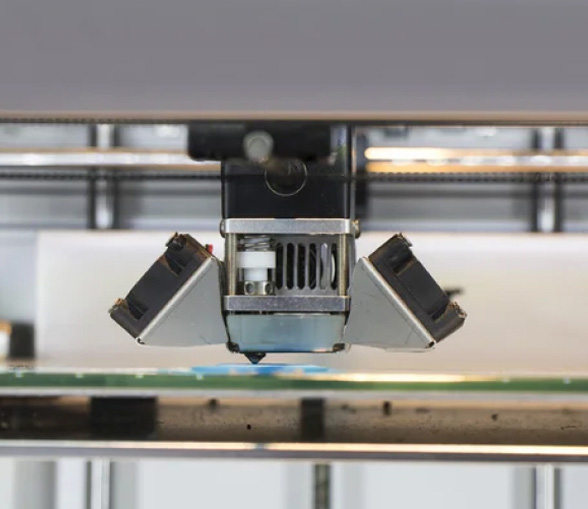

Support Removal

Removing support structures generated during the printing process is a critical step in achieving clean edges and surfaces without compromising the integrity of your parts. Our approach supports removal with the utmost care and precision. Our skilled technicians meticulously inspect each component, ensuring that all supports are removed cleanly and efficiently. Whether dealing with intricate geometries or complex designs, you can rely on us to deliver flawlessly finished parts that are ready for use or further post-processing.

Assembly and Integration

Save time and effort in the post-processing stage with our expert assembly and integration services. Our team of skilled technicians is experienced in assembling multiple printed components into complex assemblies with precision and accuracy. Whether it's joining intricate parts together or integrating electronic components, we have the expertise and resources to streamline the assembly process and ensure seamless integration. With our commitment to quality and efficiency, you can trust us to deliver fully assembled parts that meet your exact specifications.

Surface Treatmentmoval

From matte to glossy finishes, the surface treatment of your 3D printed parts plays a crucial role in enhancing both their durability and appearance. We offer a diverse range of surface treatments tailored to your specific requirements. Whether you need a protective coating to withstand harsh environments or a decorative finish to add visual appeal, we have the expertise and capabilities to deliver. Our team works closely with you to understand your needs and recommend the most suitable surface treatment solution, ensuring that your parts not only look great but also perform optimally in any application.

Functional Testing

Ensuring that your 3D-printed parts meet the required specifications and performance standards is paramount. That's why we conduct rigorous functional testing on all components before delivery. Our comprehensive testing protocols cover a range of parameters, including dimensional accuracy, mechanical strength, and material properties, to guarantee that your parts perform as intended in real-world conditions. With our commitment to quality assurance, you can have confidence in the reliability and performance of every component we deliver.

Get in Touch

Are you prepared to delve into the details of your design venture? Reach out without delay to delve into the depths of our design services and explore how we can actualise your vision.

Whether you're venturing into uncharted territory with a novel project or seeking assistance with an ongoing endeavour, rest assured, we're by your side, ready to lend our expertise every step of the journey.

Let's collaborate closely to cultivate pioneering and environmentally-conscious design solutions that fulfil your project objectives and catapult them towards resounding success.

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.