The injection molding process has changed how industries create components by combining speed, precision, and repeatability. From aerospace parts to consumer products, injection molding offers a solution for building reliable, identical pieces quickly.

Learning about the process steps and the technology behind it is important for companies aiming to innovate. In this guide, we will explore how the injection molding process works and why it has become a preferred method for manufacturing across many sectors.

Understanding the Injection Molding Process

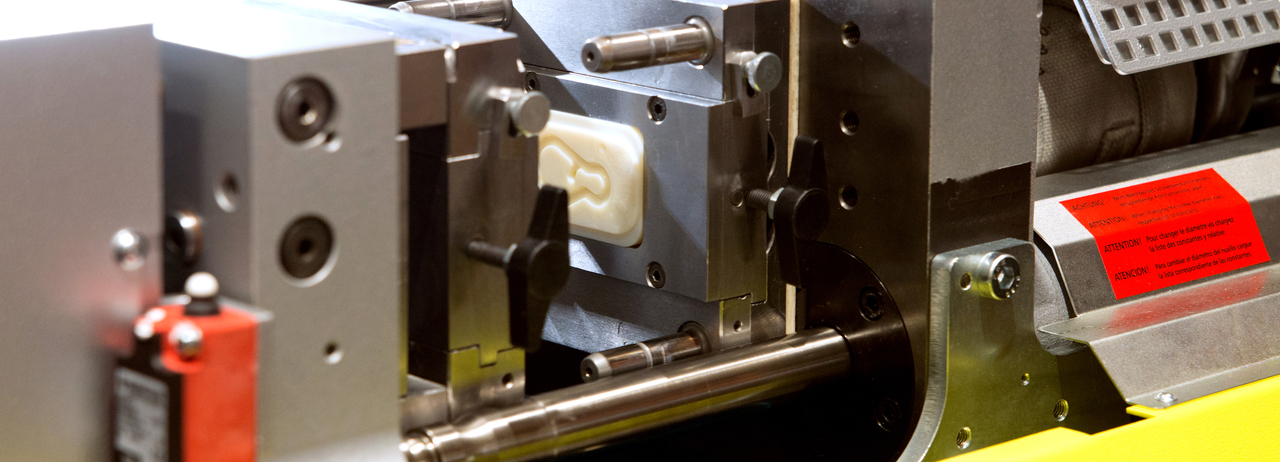

Injection molding uses raw materials, such as plastic pellets, and transforms them into finished products through a series of controlled steps. Manufacturers rely on high heat and pressure to force molten material into a metal mold shaped for the desired product.

Once the material cools and hardens, the finished part is ejected. Industries appreciate the efficiency of the injection molding process for producing large volumes of identical items.

Key Steps of Injection Molding

The injection molding process starts with clamping. Two metal mold halves are pressed together tightly to create a seal. This step prepares the mold for receiving the molten material. Next comes the injection phase. The plastic, heated into a liquid, is injected into the mold cavity under high pressure.

Companies offering online 3D printing services often use advanced modeling to predict how material will flow, reducing waste and improving design accuracy. The third step, dwelling, makes sure that the molten plastic fills every space within the mold.

This step uses pressure to avoid defects such as air pockets or weak points. Cooling then takes place. Finally, a 3D post-processing service may be needed to improve the part’s surface finish, remove minor imperfections, or prepare it for its end-use.

Materials Used in Injection Molding

Thermoplastics dominate the injection molding process due to their versatility, durability, and ability to be recycled. Common choices include polyethylene, polystyrene, and nylon. Some projects use advanced plastics capable of withstanding heat, chemicals, or mechanical stress.

Although plastics are most common, metals, glass, and elastomers also undergo injection molding with special equipment. Custom materials allow manufacturers to match the specific needs of each application.

Applications of Injection Molded Parts

Products made through injection molding are found across almost every industry. Medical devices, automotive parts, electronic housings, toys, and kitchenware all owe their production to this process.

Manufacturers depend on 3D printing services during early prototyping phases. Combining additive manufacturing with injection molding, teams can validate designs before committing to costly mold production.

Benefits of Injection Molding

One of the main advantages of the injection molding process is consistency. Every part created from the same mold will match exactly, which is vital for mass production.

Speed is another benefit. Once a mold is ready, each cycle from injection to ejection can take only a few seconds to minutes.

Furthermore, cost savings are important. Although building molds requires investment, the cost per part drops significantly for high-volume runs. Recycled plastics and optimized molding techniques further reduce material waste.

When combined with a trusted 3D post-processing service, injection-molded parts achieve the surface quality and appearance needed for consumer-facing products or specialized technical uses.

Challenges in Injection Molding

While injection molding is an efficient and versatile manufacturing process, it is not without its challenges. One of the primary hurdles is the time and careful planning required for upfront mold creation.

Developing molds that meet design specifications can be complex and costly, and any errors in this process can result in defects such as warping, sink marks, or inconsistent finishes. These issues can compromise the quality and aesthetics of the final product.

Additionally, quality control plays a key role in preventing defects throughout the production cycle. Monitoring factors like injection speed, pressure, and cooling times is important to achieving consistent results. Inaccuracies in any of these parameters can lead to product variability and reduce overall reliability.

To mitigate these risks, continuous monitoring and adjustments are needed to maintain high standards and guarantee that each product meets customer expectations.

Achieving Precision with RMA Engineering, LLC

At RMA Engineering, LLC, we help bring your concepts to life through expert prototyping, precision manufacturing, and streamlined distribution support. No matter if you’re launching a new product or refining an existing design, our experienced team is here to guide your project through every stage of the injection molding process.

From material selection and tooling design to production and post-processing, we make sure your components are delivered with accuracy, consistency, and efficiency.

With personalized service, advanced technologies, and a commitment to quality, RMA Engineering, LLC turns your ideas into production-ready solutions built for success. Let’s bring your next innovation to life—connect with us today to get started.

Recent Posts

How To Design A Product That Stands Out In The Market

13 Advantages Of Injection Molding For High-Volume Manufacturing

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.