The Ultimate Guide to Choosing the Right 3D Printing Service

PETG (Polyethylene Terephthalate Glycol) is a widely used thermoplastic in 3D printing due to its balance of strength, flexibility, and heat resistance. This material combines the durability of ABS with the ease of use of PLA. It’s a preferred option for many applications, from prototyping to functional parts.

One of the key aspects of PETG 3D printing is its adaptability to design for manufacturability. It makes sure that printed parts meet structural and functional requirements while being cost-effective.

Its resistance to chemicals, impact strength, and minimal warping make it a reliable material for industrial and consumer-grade prints alike.

Key Benefits of PETG 3D Printing

Durability and Strength

PETG is known for its high tensile strength and impact resistance. This makes it suitable for functional parts that need to withstand stress. Different from PLA, which can become brittle over time, PETG maintains its structural integrity even under mechanical pressure.

The durability is particularly valuable for parts that will experience repeated use or exposure to physical force. Be it used in manufacturing, automotive applications, or consumer goods, PETG offers a level of robustness that makes sure of longevity in finished products.

Additionally, its ability to maintain strength across a variety of environments makes it a reliable material for both indoor and outdoor applications.

Flexibility and Toughness

While ABS comes with durability, it can be prone to cracking under stress. PETG bridges this gap by providing a degree of flexibility while maintaining toughness. This helps reduce the likelihood of breaking under load. This characteristic makes PETG particularly useful for applications requiring parts that absorb mechanical shocks or undergo repeated movement.

The balance between strength and flexibility allows printed components to handle pressure, minor bending, and drops without significant damage. It’s an ideal material for enclosures, brackets, and other mechanically demanding parts.

Chemical and Moisture Resistance

PETG is resistant to a wide range of chemicals, oils, and moisture. It’s an excellent choice for applications exposed to harsh environments. Unlike PLA, PETG does not degrade easily when exposed to humidity. This property is beneficial for industries where exposure to solvents, cleaning agents, or industrial fluids is common.

Additionally, PETG's ability to withstand moisture without warping or breaking down makes it an optimal choice for outdoor applications. It is also ideal for medical devices and food-safe products that require regular washing or sterilization.

Minimal Warping and Easy Adhesion

One of the biggest challenges in 3D printing is warping, particularly with materials like ABS. PETG significantly reduces this issue. It allows for better bed adhesion and more consistent layer bonding.

This results in smoother, more accurate prints with fewer defects. The enhanced adhesion means that PETG is well-suited for printing large objects. It remains stable throughout the process without the risk of corners lifting or layers delaminating.

Its ability to maintain dimensional accuracy with minimal warping makes PETG a preferred material for engineering-grade prototypes. It is also ideal for functional parts requiring precise tolerances.

How to Optimize PETG Printing for Best Results

Recommended Print Settings

Achieving high-quality prints with PETG requires precise tuning of various settings, including temperature, print speed, and bed adhesion.

The extruder temperature should typically be set between 230°C and 260°C. This guarantees proper filament flow while preventing clogging or under-extrusion.

If the temperature is too high, it can lead to excessive stringing, where fine threads of filament stretch between different parts of the print. If the temperature is too low, the layers may not bond properly, leading to weak structural integrity.

The heated bed plays a key role in preventing warping and improving adhesion. A temperature range of 70°C to 90°C delivers the best results. This allows the first layer to stick firmly to the print surface while avoiding excessive softness that might cause deformation.

Proper print speed is another factor to consider. Printing PETG at a moderate speed of 40 to 60 mm/s balances layer adhesion and print precision. Printing too fast can result in poor bonding between layers, while printing too slow may lead to excessive heat buildup.

Cooling is another important element in achieving optimal results. PETG benefits from moderate cooling, with a fan setting between 30% and 50%. While cooling helps to reduce stringing and improve surface finish, too much cooling can weaken layer bonding.

Bed Adhesion Techniques

PETG adheres well to heated beds. However, additional adhesion methods can help create a more stable first layer–preventing warping and lifting at the edges. Applying a PEI sheet to the bed brings an even surface that promotes adhesion without the need for adhesives.

For users printing on glass or other surfaces, painter’s tape or a glue stick can help PETG stick more effectively. Applying a thin layer of glue creates a removable bond that holds the print in place while allowing for easy removal once printing is complete.

Proper first-layer calibration is also essential. The nozzle should be positioned at the right height to allow the filament to adhere well without being too close. This might cause over-extrusion and smudging.

A well-calibrated first layer sets the foundation for a successful print. This helps minimize the chances of print failures caused by lifting or improper adhesion.

Avoiding Stringing and Oozing

PETG is known to produce fine stringing if retraction settings are not properly configured. Stringing occurs when melted filament leaks from the nozzle as the print head moves between different sections.

Adjusting the retraction settings can significantly reduce this issue. Increasing the retraction distance to a range of 4 to 7 mm–depending on the extruder type–helps pull back the filament to prevent unnecessary oozing. A retraction speed of 25 to 40 mm/s works well to minimize material drips while maintaining consistent extrusion.

Enabling coasting is another effective way to prevent excess filament from accumulating at the end of a movement. Coasting stops filament extrusion slightly before the end of a printing segment. This reduces pressure buildup inside the nozzle and eliminating blobs.

Additionally, setting the print temperature slightly lower within the PETG range can help reduce oozing without compromising layer bonding.

Print Speed Considerations

Maintaining an appropriate print speed is critical for achieving strong layer adhesion while preserving precision and detail. PETG requires a slower print speed compared to PLA to make sure that each layer bonds correctly.

A speed range of 40 to 60 mm/s comes with the best results. Slower speeds allow more time for the layers to fuse together properly. This leads to stronger prints with fewer gaps or inconsistencies.

For intricate parts, reducing the speed further can help enhance detail quality, preventing defects caused by rapid movements. Conversely, overly slow speeds can cause heat buildup and sagging.

For that reason, balancing speed and cooling settings is necessary for optimal results. Printing PETG at a moderate pace reduces overall warping and enhances surface smoothness. It’s a preferred choice for both industrial and consumer applications.

Common Challenges When Printing with PETG

Overheating and Material Flow Issues

Excessive heat can cause significant issues when printing with PETG. This leads to problems such as blobs, stringing, and filament oozing. These imperfections occur when the nozzle retains too much heat, allowing filament to continue extruding uncontrollably.

To mitigate this, adjusting the cooling fan to a moderate setting between 30% and 50% helps regulate temperature while maintaining proper layer bonding. Additionally, lowering the extruder temperature by a few degrees can prevent overheating without compromising adhesion. This results in smoother and more controlled prints.

Layer Adhesion Problems

Weak layer adhesion is another common issue when printing with PETG. If prints begin to separate between layers, it is likely due to insufficient heat or improper extrusion settings.

Increasing the extruder temperature in small increments of 5°C can enhance bonding and reduce the risk of delamination. Slowing down the print speed can also contribute to stronger adhesion. This allows each layer to properly fuse before the next one is deposited.

Guaranteeing the nozzle is clean and free of obstructions is equally important. Clogs or inconsistent extrusion can negatively impact print integrity.

First Layer Adhesion Difficulties

The first layer is the foundation of any successful print, and poor adhesion can lead to warping, lifting, or outright print failure. If the first layer is not adhering correctly, increasing the bed temperature can improve surface grip and minimize curling at the edges.

Using an adhesive aid, such as glue, hairspray, or a PEI sheet, delivers additional support by creating a more adhesive surface. Proper nozzle height calibration is also critical—if the nozzle is too high, the filament may not stick properly; if it is too low, the material can smear and cause extrusion inconsistencies.

Making fine adjustments makes sure the best possible adhesion and sets the stage for a successful print.

PETG vs. Other 3D Printing Materials

PETG vs. PLA

PLA is easier to print but lacks the impact resistance and flexibility of PETG. PETG, on the other hand, offers better durability and heat resistance. This makes it a superior choice for functional parts.

PETG vs. ABS

ABS is known for its high strength and heat resistance. However, it requires a heated enclosure to prevent warping. PETG offers comparable strength without the hassle of ABS’s strong odor and printing difficulties.

PETG vs. Nylon

Nylon offers greater flexibility and wear resistance but requires a high-temperature extruder. PETG is easier to print and delivers an excellent balance of strength and ease of use. Therefore, it becomes more accessible to a wider range of users.

Applications of PETG in 3D Printing

Industrial and Engineering Components

PETG is widely used for manufacturing jigs, fixtures, and mechanical components that require impact resistance and durability. Its chemical resistance also makes it ideal for industrial environments.

Prototyping and Product Design

Because PETG is easy to work with and brings excellent mechanical properties, it is a popular choice for prototyping. Engineers and designers can create functional models that closely resemble final production parts.

Medical and Food-Safe Applications

PETG is commonly used in the medical industry for creating protective equipment and custom prosthetics. Many PETG filaments are also food-safe. This makes them ideal for kitchen utensils and containers.

Best Practices for Post-Processing PETG Prints

Sanding and Polishing

PETG prints can be sanded and polished for a smooth finish. Using fine-grit sandpaper (400+ grit) and wet sanding techniques enhances surface quality without melting the plastic.

Painting and Coating

PETG can be painted with acrylic-based paints after applying a primer. Clear coats can also enhance transparency and give additional protection.

Gluing and Bonding

Unlike PLA, PETG can be welded together using solvents like dichloromethane. This allows for the seamless joining of large parts without weakening the structure.

PETG is one of the most versatile and reliable materials for 3D printing, offering strength, durability, and ease of use. By optimizing print settings, managing common challenges, and applying best practices, you can achieve high-quality results for a wide range of applications.

At RMA Engineering, LLC, we specialize in advanced 3D printing solutions tailored for industrial and commercial applications. Are you looking for high-performance materials or expert guidance? We are committed to helping you achieve design for manufacturability without compromising quality.

Contact us today to learn more about how PETG can enhance your next project.

Recent Posts

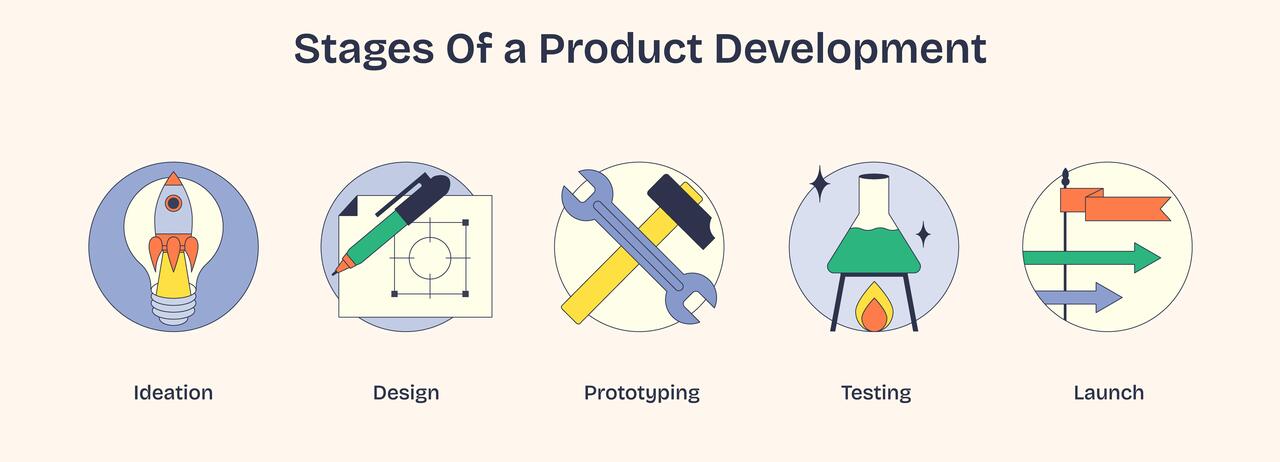

The Key Stages Of Product Development: A Complete Guide

How To Design A Product That Stands Out In The Market

Contact Us

For custom quotes please fill out the form below. Or email us at info@rmaengineering.tech.